T’S ALL ABOUT the touch and feel in the wide-format market. The tactile nature of our industry is what so many people missed when tradeshows and in-person events were canceled due to the pandemic. Virtual meetings were fine placeholders, but they lacked the ability to touch and feel the printed fabric, vinyl, or film.

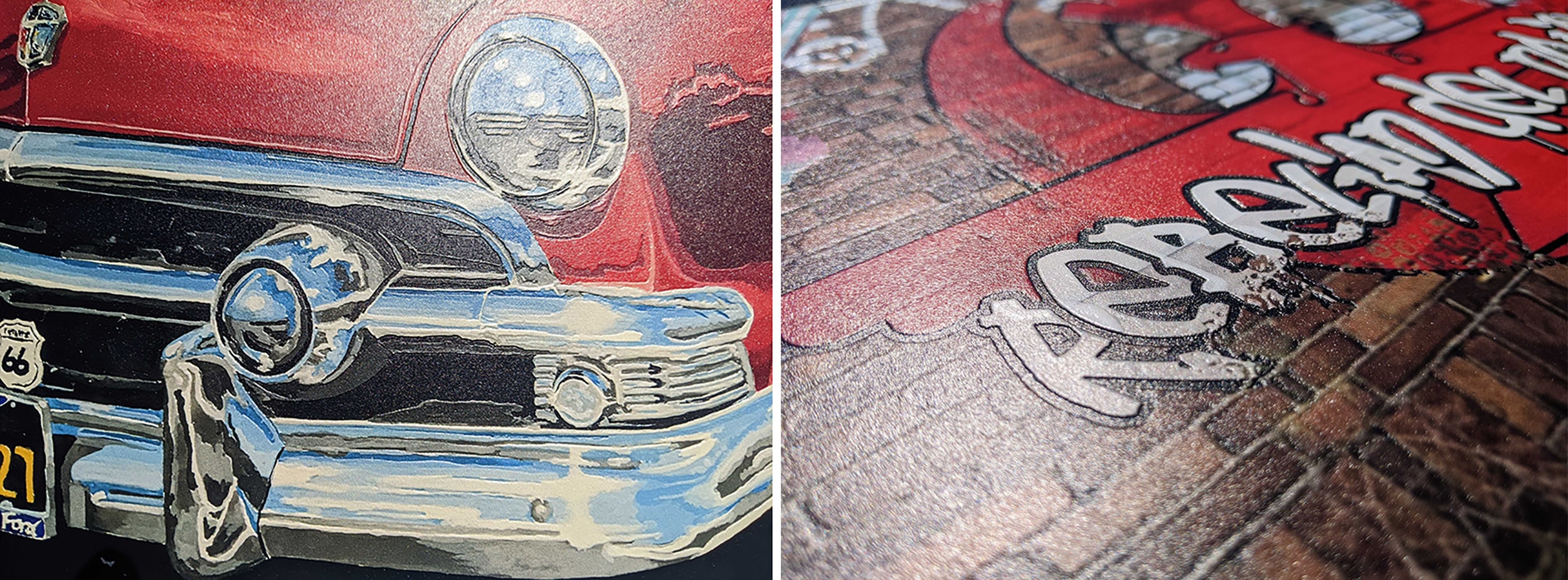

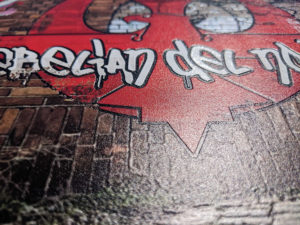

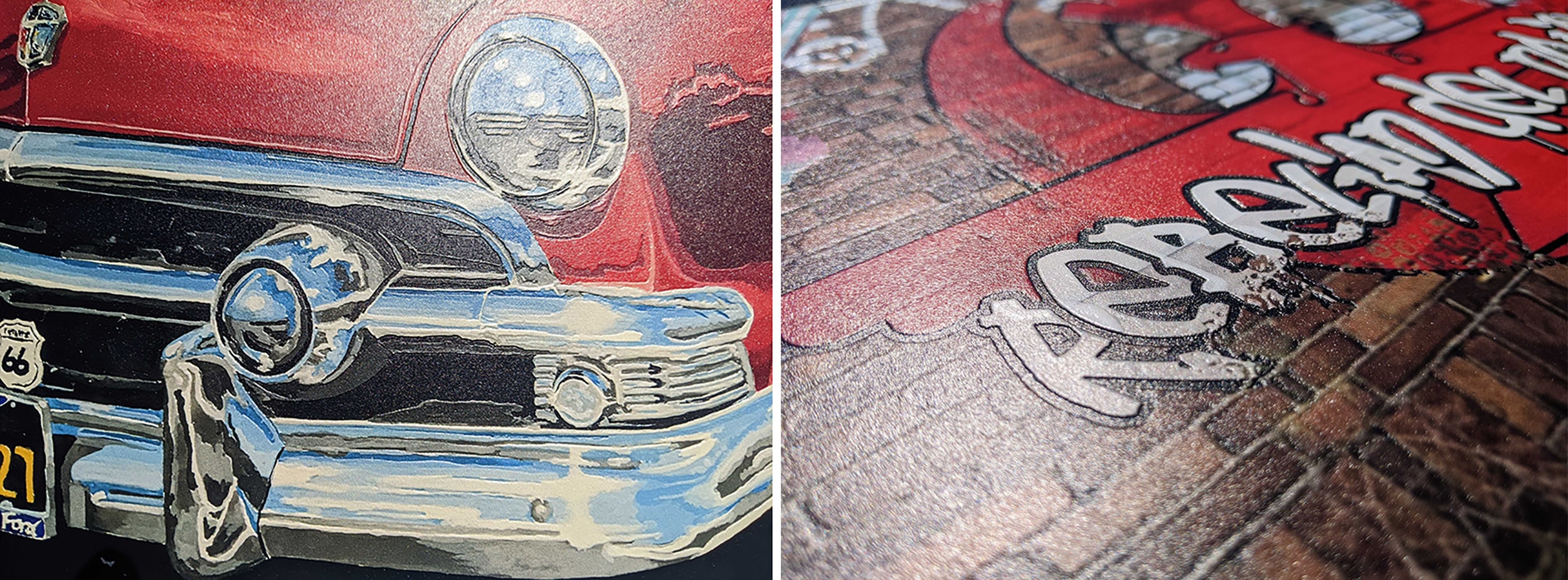

This multi-dimensional, printed text on wood signs was created to elevate a standard project for a client.

As printing technology advances, many PSPs are interested in an even greater touch and feel effect with dimensional textured printing: using multiple layers of ink to create texture and dimension. However, it can be a very expensive and time-consuming process. While most PSPs have the ability to do it, the time and cost it takes to print doesn’t add up, especially when presenting the final price point to a client. Lots of in-house testing is happening, but no projects are being sold.

Image360/Allegra Printing in Lexington, Kentucky, is working toward bridging the gap between testing and selling dimensional textured printing.

“We have used the process in a few different ways on different projects,” says Mark Stovall, COO, Image360/Allegra Printing.” We have used our EFI Pro 24f flatbed printer to create wood grain backgrounds for menu boards, multi-dimensional text on acrylics and wood signs, as well as numerous other applications. Each time we do this, we are either trying to embellish a project to elevate it beyond the norm or achieve a look and feel at a cheaper or faster alternative. There’s a little more design work involved and a few more print files, but the final product is worth it.”

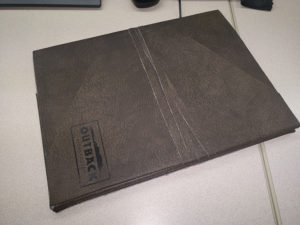

Stovall was approached by a marketing/branding agency based out of Louisville to create prototype menus for a consumer test panel. “They requested eight copies of each of the three concepts,” he says. The shop was given concept art and renderings, but no specifications. “One of the menu designs included a backer board that was to be made from ‘reclaimed’ wood. One of the concerns from my client was the weight of actual wood as well as the thickness of it to be able to hold up and abuse in a restaurant.”

Advertisement

Image360/Allegra Printing printed a wood texture on a 6mm sheet of PVC and routed to size and shape.

Image360/Allegra Printing was given a very short timeline to produce the prototypes. “By the time we had worked out some of the details, I did not have time to source a lot of the components of the menus,” says Stovall. “I had contacted several lumber suppliers and cabinet makers to source some wood backer boards, but unfortunately there was nothing available that would fit my needs.” This is when he decided they would be better off printing a wood texture on a 6mm sheet of PVC and routing to size and shape. “We took an image of reclaimed wood and created a multi-layer version to be able to add grain and recesses to the final surface.”

The shop used its EFI Pro 24f flatbed printer to print three layers of ink, four different times to achieve 12 layers.

The print shop used its EFI Pro 24f flatbed printer to print a color/white/color profile, creating three layers of ink, four different times to achieve 12 layers. “This was a compromise of production time and final texture that we found to be best suited for our needs,” says Stovall. “The end result turned out to be a great, lightweight, cost-effective, and a visually attractive alternative to actual wood.”

Image360/Allegra Printing uses the multi-layer ink approach when they want to add visual separation between the substrate and the printed element, whether it’s text or a logo. “We have also created some debossed and embossed style signs,” says Stovall. “These are fun ways to kick up the final product a notch or two and be able to provide a little extra without having to add an additional machine to the production floor. Small elements of added value go a long way in customer satisfaction and setting yourself apart from the competition.”

Advertisement

Textured prints produced and designed by Fastsigns Oakland; Fastsigns Hayward team members Bennie Dominguez (brick wall) and Kelly Paiz (vintage car headlight). Photo credit: Chris Gaeta.

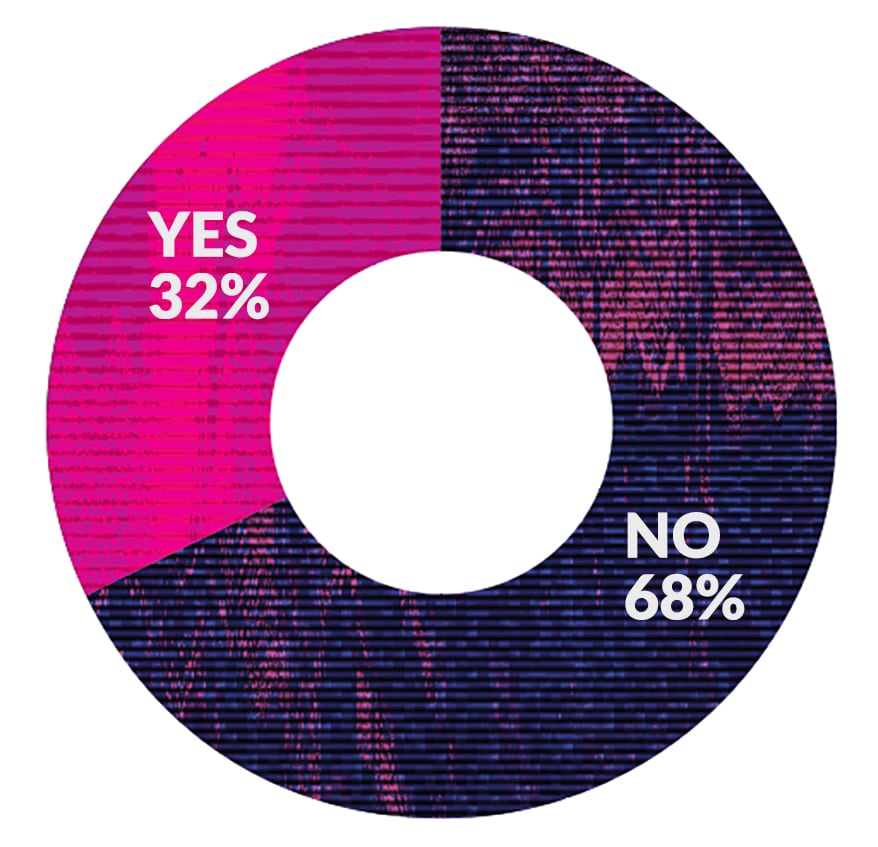

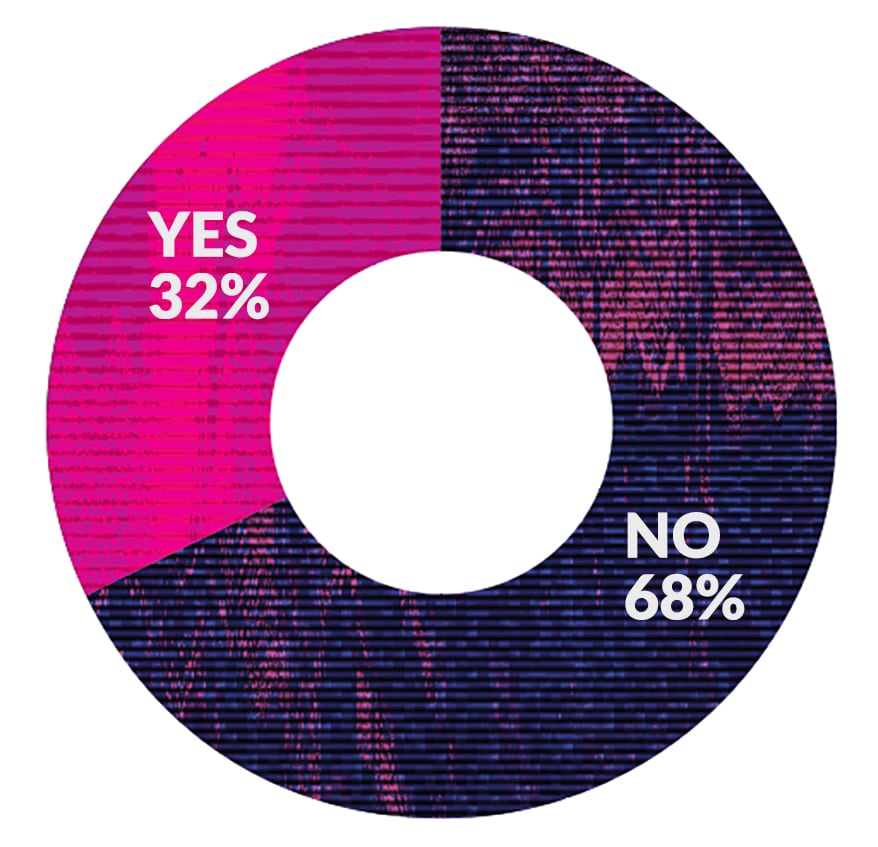

We asked the Brain Squad:

“Do you offer dimensional textured printing?”

- We do, but it’s very limited and it’s difficult to explain to clients how to customize in three dimensions. We haven’t had any of the digital dimensional projects come to fruition yet, primarily due to costs. There are only a few machines capable of producing the effect, and the one we have considered requires using their base material, which is limited and expensive. There also isn’t a whole lot of info as to how to set up files and specify the amount of dimensionality and the means to clearly explain to customers what controls they would have over the shape of the dimensioned bits. I’m sure these controls exist, but because we are working with a partner on these it’s more difficult to get all of the details. I like to play around and test things to get the best results! You can build the dimension using clear or colored ink or a combo, which is super cool, just not a signage product. — Jon Sherman, Flavor Paper

- So far there hasn’t been the option for fine art printing. We would love to offer something along those lines if we could do so without compromising quality. — Jim Dittmer, JDA Creative Color

- We used to offer textured varnish for digital print on corrugated, but not enough clients purchased. — Kristi Duvall, The BoxMaker

- We can offer dimensional textured printing; however, that would require some R&D prior to feeling comfortable as a paid project. The benefits are having a more attractive piece, however I have yet to see a standalone textured and dimensional graphic without some sort of vanilla base to offer contrast, movement, and interest. We haven’t offered this product because our latest tests have shown the printer that is fast enough on how it builds the texture has size limitations and the larger flatbed is slower in building the texture. It is not necessarily expensive as it is not efficient. How do we charge for the time it takes to do a sizable project? — Linda Fong, Fastsigns Oakland; Fastsigns Hayward

- We do offer it, but we find the added layering can also greatly add to the cost, wear, and tear on machinery and reduced speed and efficiency. — Derek Atchley, Atchley Graphics

- Yes, we can do it, but it’s all about managing expectations. Test runs are never a bad idea. We tested it by creating a wood panel out of white PVC. The wood grain was clearly visible. It’s definitely a nice option to have in the tool kit! — Gina Kazmerski, Image360 Woodbury

- We have explored using this technology primarily for ADA applications, but we have not adopted it yet. It is something we think has value, but it is not a high priority at the moment. — Wade Neff, Strategic Factory

- We can produce it, but the cost is usually not worth it to the customer. — James Dietz, Lake Erie Graphics

- We do offer dimensional printing. The print time, proofing, and file preparation are challenging. But it is rewarding for someone that likes to look for the details. — Ryan Clark, Direct Edge

- Love this technology/application. Have yet to put it into practice. — Jim White, Go Graphix

PHOTO GALLERY (39 IMAGES)

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Blue Print3 weeks ago

Blue Print3 weeks ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago