THE BEGINNING OF A NEW year is generally a good time to reflect on the decisions of the past year, to plan for the next, and to begin turning New Years’ resolutions into reality. The following offers a look at some of the most recent feedback from our online VIP survey group, the Brain Squad. Peruse their answers to questions about their investment plans, favorite technology, and biggest achievements of the past year. Perhaps you’ll find inspiration or ideas to apply to your own business.

Epson SureColor V7000 UV Flatbed Printer

How much do you plan to invest in your business during the next 6 months?

- We are planning on updating some aging equipment, including some printers, router and maybe even a laser. We have to stay true to who we are and what’s going on in our own environment. If you’re going to continue to be seen at the top of your industry by your customers, partners, and peers, you can’t run in place. So, you have to consider at least upgrading certain kinds of equipment depending on their condition, the products you’re using and the training your people have. There’s always an eventual payoff for having that mindset. That said, you may have to push certain things off another six months if they’re large expenditures, and that’s OK. A general theme I’m hearing is that people aren’t eliminating investments as much as saying, “Not yet, but we plan to put money into that.” Having a conversation with your most trusted external advisors, like your banker, financial advisor, accountant, and attorney is also crucial. Bringing in highly specialized minds from the outside can give you the perspective (and peace of mind) to make these decisions. They can help you consider any consequences you wouldn’t otherwise have thought about. — Gary Schellerer, ER2 Image Group

-

Business is tightening up in Australia. We made some capital investment before the end of our financial year (June 30) that will see us through for a while. Ideally we would like to put on more staff, but the talent pool is small and it is hard to attract workers. — Derek Michalanney, Signageworld

- I need a larger staff to manage office operations. — Carmen Rad, CR&A Custom

- I have my eye on the Epson SureColor V7000 UV Flatbed Printer to help speed up our output processes and be able to utilize staff in other capacities. — Tami Napolitano, Awesome Graphics

- I plan to hire additional staff, purchase two new pieces of equipment – maybe three – and make improvements on my building. — Britt Hoff, H n H Sign Company

- Our new location needs walls and additional electrical outlets and networking access. We will spend about $5,000 on this. We are also considering a laser cutter or 3D direct-to-substrate type of printer for ADA and other dimensional signs. — Ann Durso, Express Sign & Graphics

How much do you plan to invest in your business (e.g., new equipment, additional staff, etc) during the next six months?

Advertisement

What processes, strategies, and technologies have made the biggest difference for your business?

- Our wide format digital cutter, a Summa F1832 72×126, has been a favorite tool of ours. Not only for fast and efficient finishing of all types of printed media, but also a great tool for fabricating 2D into 3D products. It’s a maker’s favorite toy! — Derek Atchley, Atchley Graphics

- Our HP R2000 printer allows us to quickly turn a variety of jobs with great color and white ink capabilities. Our Zund G3 Router offers precision processing – this machine runs all day and rarely needs maintenance. Our Cut Worx CWT application table cut our labor in half and consistently processes and masks our printed work. — Rob Matthews, M3

- Our Roland roll-to-roll printers are the profit engines of the shop. If they are running, we are making money. — Tim Bezner, Westmount Signs and Printing

-

The new Epson Resin printers have found a soft spot in my heart. We bought two of those machines, and they replaced our latex and solvent printers. Our installers love the way the printed 3M material lays down on a vehicle and the colors are always amazing. — Tami Napolitano, Awesome Graphics

- I can’t say enough good things about the online software Airtable. We use it to manage many important parts of our business, from scheduling to employee training to vendor, installer and material lists. — Wade Neff, Strategic Factory

- Seal laminators. They are the most reliable equipment in the building. After 15+ years, they’re not obsolete and very rarely have any issues. — Malcolm Gieske, IDWraps.com/Identity Group

- The ability to have multiple printers all connected and providing revenue. One person and two designers can now produce more square footage of print material than ever before. The revenue per employee has really increased — one of the business goals I have. — Kim Magraw, Vivid Sign

- We made the switch to a cloud-based and paperless system in 2018. It was a painful process, but now we look at our old job jackets and hanging file folders with old notes about WIP and A/Rs and wonder how we managed. If we had not made this transition, I’m not sure how we would have navigated 2020/2021 as well as we did. — Linda Fong, Fastsigns Oakland; Fastsigns Hayward

- Moving SuperGraphics to a new building has streamlined our process so much we have increased our efficiency by over 30 percent. Our former building was three levels, and now we have two: offices and production floor. — Jacob Meier, Supergraphics

- Online production tickets. — Rick Mandel, Mandel Graphic Solutions

- We switched from Lambda to completely digital (printing) and added a few cutters that have really contributed to our speed and quality. — Diana Herrera, AP Imaging

- We added a hybrid printer and complementary Colex cutter/CNC. We also added a small laser for cutting, but not so much for etching. — Pat Dacy, 3V Signs & Graphics

- Capability to use apps and software for project management has been huge. — Trey Matula, Picture This Wraps and Graphics

-

Adapting an ERP, MIS, CRM, and many other three-initial programs will lead anyone to stick a fork in their eye. — Ryan Clark, Direct Edge

- We implemented new processing systems. First it was Monday.com; now it’s Oodo. — Carmen Rad, CR&A Custom

- Faster UV printheads and printers using magnetic movement rather than a belt system on flatbeds. — David Kaiser, Digitype Design

- Vanguard Printers – these people started out as a print providing company but couldn’t find printers with features that would answer their needs, so they started to build their own (CET Color at the time they started). Very rarely are there issues/breakdowns. — David Kaiser, Digitype Design

Vanguard VK3220T-HS UV flatbed printer

How do you evaluate the performance of your business?

- We use a combination of recurring revenue, daily sales booked, and CRM pipeline for leading indicators. All of these are tracked in a combination of order software and CRM. — Kristi Duvall, The Boxmaker

- We use a weekly scorecard with KPIs (sales, margin, scrap, on time percentage, quality metrics, inventory levels, A/R aging), monthly financials, annual reviewed financials, and culture evaluation. — Brian Adam, Olympus Group

- My business is run by the premise of quality, service, and fun. Employees know to have a productive day and have fun. Most importantly, if we look at an item we produce and it doesn’t look good, we ask, “would we pay for it?” If the answer is “no,” we do it again. — Tommy Melendez, Master Graphics NYC

-

We have an informal process: We compare month-to-month and year-to-date with 2 years prior, with an assumed 5- to 10-percent growth. — Diana Herrera, AP Imaging

- We operate using the EOS system for managing the issues of running a business. There are over 100 different metrics tracked daily for all aspect of the business, from sales to operations to AR/AP and finance. Utilizing our MES and other internal applications, some of the key metrics include: revenue per employee, equipment utilization, rework, material use, labor and overtime, financial, estimated versus actual percentages, contribution margin, gross margin, EBITDA, daily revenue and estimates, on-time delivery, and percentages of all categories against top-line revenue. — Brian Hite, Image Options

- Of course, the two biggies are revenue and profitability. Beyond that we look at dollars per customer, dollars per project, and percentage of estimates that convert to orders. There are a lot of time metrics as well – time to estimate, time to convert, time to complete. Essentially where you want to see change in your business, you must track current data to understand where and how change is possible. — Wade Neff, Strategic Factory

- We are hyper-focused on reducing waste, in alignment with our EcoFormat efforts. We know what materials are accessible to our peers because we all share the same supply chain, and we are aware of how much waste grand format can produce on average. This helps us identify our benchmark of what is common, compare it to our goal, and measure our progress. Our biggest trackable metric is how many tons we recycle on a monthly basis. This is achievable through our partnership with a major recycler (and long-time client) who offers these solutions to businesses across the state. — Jacob Meier, SuperGraphics

- We evaluate our performance in a very traditional method using standard budgeting and financial statements. We pay very close attention to spending and gross margin. Making the investment with time and money to truly capture your real costs is vital. It has been an ongoing improvement project for us for a decade. There is a lot more to calculating cost than direct labor and materials. — Jared Smith, bluemedia

-

We review financials monthly. We review open orders/WIP, and sales versus previous years and months. We pay very close attention to COGS and work to retain good margins on all projects. As far as comparing with other businesses, we do not track or evaluate that except against published information in our industry magazines. In general, we meet or exceed the averages in sales per employee, productivity, and profitability when compared to national results. — Ann Durso, Express Sign & Graphics

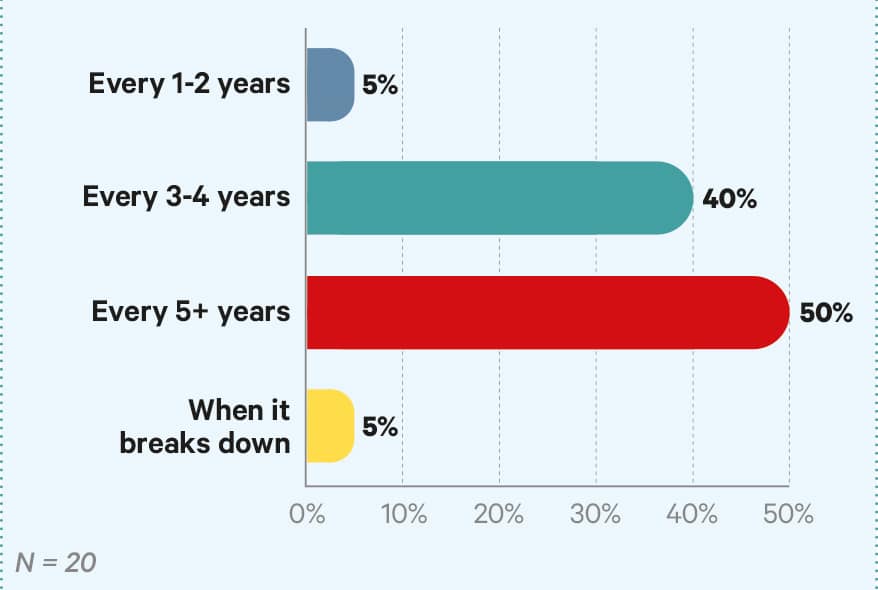

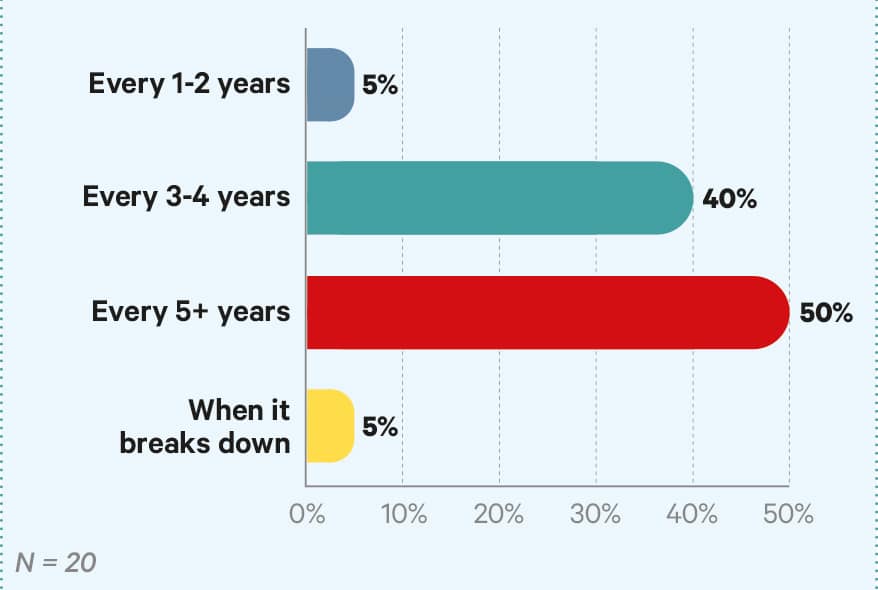

How often do you update or replace your larger, more expensive equipment?

Have you recently launched any high-impact, low-effort initiatives?

-

Two strategies that we’ve launched are emails that drive to our blog content and unpublished landing pages on our site that are vertically oriented. They are unpublished because they are often on subject matter (like healthcare) where we have competing clients but we want to be able to show our healthcare breadth to a potential client. Our blogs combined with emails definitely get search spikes. — Rebecca Lyman, DCG One

- A framed hiring sign in front of our shop. It’s so much less pricey than an Indeed ad! — Malcolm Gieske, IDwraps.com/Identity Group

- We launched a series of sales incentives with the sales team to inspire action and shift behavior. It offered additional income for those willing to focus on products where we needed to gain volume. — Kristi Duvall, The BoxMaker

- I am a productivity geek, so when I have a repeat-order graphics program, I tend to use some of the great web tools, such as Airtable, Notion, Evernote, Dropbox, etc., to semi-automate or at least serve as a document hub to cut down on email traffic. Anything that cuts down on emails is a worthwhile endeavor! — Darren LoPrinzi, Color Reflections

- Asking clients for a referral as well as a Google review is super simple, and most clients have no problem with that! — Derek Atchley, Atchley Graphics

- Printing for other companies. We’ve invested in more print firepower, which allows us to take an increased load of wholesale work. We don’t have to sell it, design it, or install it. — Rob Matthews, M3

- We created a design/build estimating workflow for the complex or lengthy types of projects. The operations side is almost seamless with what the account managers envision for their clients. Work orders are now written up with the most updated methods since we practice continuous improvement. — Linda Fong, Fastsigns Oakland; Fastsigns Hayward

What’s the Brain Squad?

If you’re the owner or top manager of a U.S. wide-format printing business, you’re invited to join the Big Picture Brain Squad. Take one five-minute quiz a month, and you’ll be featured prominently in this magazine, and make your voice heard on key issues affecting wide-format professionals. Sign up here.

Advertisement

VEHICLE WRAPS + GRAPHICS3 weeks ago

VEHICLE WRAPS + GRAPHICS3 weeks ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Case Studies3 weeks ago

Case Studies3 weeks ago

Case Studies1 week ago

Case Studies1 week ago

Benchmarks3 weeks ago

Benchmarks3 weeks ago

Press Releases2 months ago

Press Releases2 months ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Press Releases2 months ago

Press Releases2 months ago