AT DIRECT EDGE MEDIA, mastering a seamless post-production process actually begins with the pre-production process. Before the print communications company, with locations in Orange County and Anaheim, California, and Denver, even begins to think about cutting, laminating, sewing, kitting, and shipping, they’re focused on perfecting what happens before printing.

“If it’s organized and dialed in, then your post-production is more streamlined because your employees know what to do and can hit the ground running,” says Ryan Clark, president, Direct Edge Media.

The major benefit to digital printing and cutting is the opportunity to print prototypes for clients. “We like to make complete one-offs before the job is done so we can show the client and the production team what the final product will look like and that it’s been signed off by the client. That way you’re not having an operator run a thousand sheets that are totally wrong,” says Clark.

To really bring the customer’s concept to life, Direct Edge has its own mock-up retail store in-house (see above.) “We will set up the display entirely with the design so the client can walk over to the glass window and see if it’s right,” says Clark. They’re able to see any changes made and approve of the final look. “The pre-production is done so the post-production team can have the physical sample to compare.”

Because many of Direct Edge’s clients are shut down due to COVID-19, Clark and his team will send a photo of the replica store or invite them into their space. “Of course there are people who are picky and they want to tweak, but that’s the advantage of digital,” he says. “We can change the color, make this, fold, make this three inches wider, etc.”

Advertisement

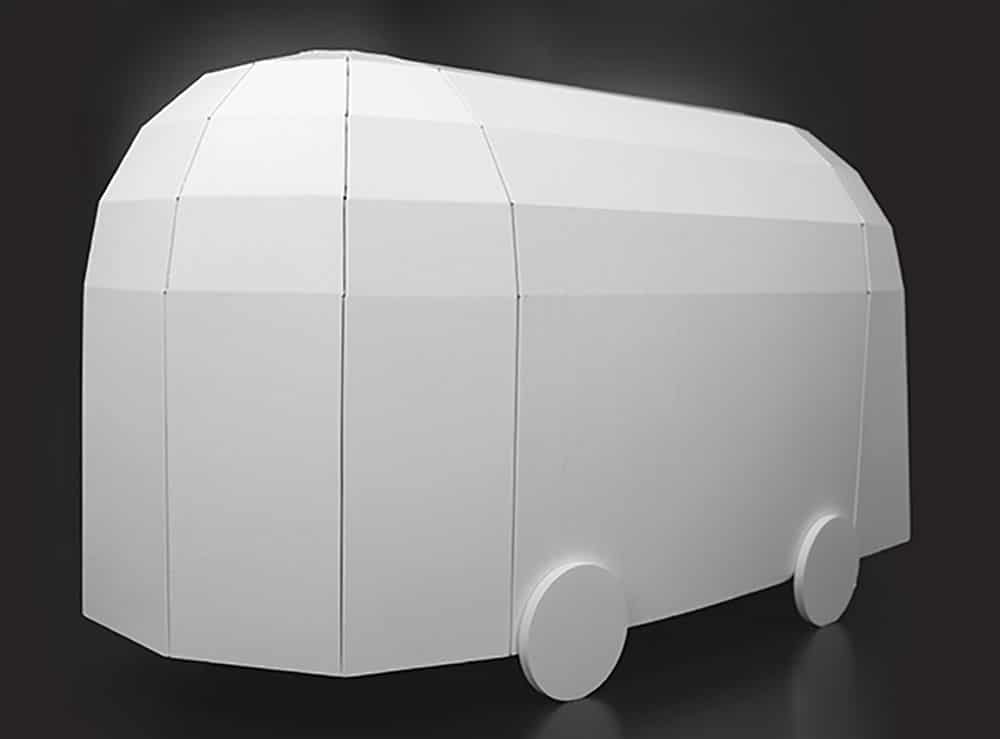

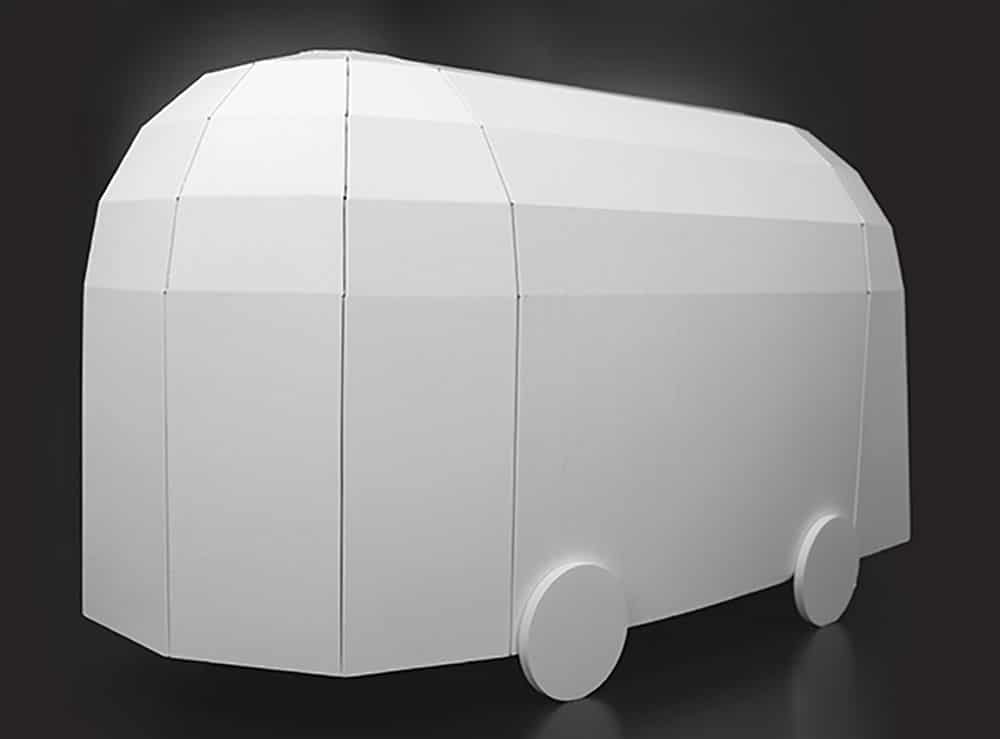

Sometimes the shop and the clients can go back and forth on multiple prototypes in just one month. Clark says it really depends on how complicated the project is; other times it’s more conceptual. A good example of this is a recent Airstream trailer they created out of cardboard. “That’s where our designers may spend a long time figuring it out,” he says. But at the end of the day, it’s better for the post-production team to have the approved prototype because they know what the final product will look like before the print process even begins. Direct Edge Media relies heavily on their Zünd cutters. They have four at their Orange County location; technically five, as one has a double-head. “We’ll cut it four times on the Zünd to make sure it’s right,” says Clark..

Your Team

When asked the age-old question, “What’s your bottleneck?” Clark turns to his employees. “No matter what, it’s always going to come down to each member of the team setting up the next one for success.” He stresses the importance of hiring great people and taking preventable measures like training. “Training is difficult, especially if you have high turnover,” he says. “As our company is growing, it’s difficult to maintain our high-quality standards while still working around the clock or on weekends.

Training our operators to know how to run a particular piece of equipment is the first step. Having them be able to look at the bigger picture of the entire project is really the goal. Does the banner match the postcard, and how will they both fit into the same box?”

Shipping

Clark could talk for days about his shipping woes. Since the shop opened in 2011, the Direct Edge Media team has learned (the hard way) that something is inevitably going to get off thrown off a truck or be the first box to drop from a four-story conveyor belt. They’ve spent a lot of time finessing their packaging tricks. “Acrylic boxes are really fragile so we will double box, put in foam corners, and then box it again,” says Clark. “You have to assume if it’s going to drop 15 feet, it’s going to break it, even if you wrap it in bubble wrap five times,” which gets into third-party shipping, he says. “A lot of companies want us to use their UPS or FedEx number. The breaking of the box is then on the client’s end, but they don’t know that so we try to do everything through our accounts so we can handle that and be full service. UPS and FedEx make it really difficult to file a claim so we include it in our overall service plan.” If something happens (like a perfectly packaged box is run over by a truck – true story), Direct Edge Media will figure it out and deal with it so the client doesn’t have to.

Packaging and shipping is the biggest stressor in the post-production process for Clark and his team because once it’s left the shop’s doors, they have no control over what happens from that moment to when it gets to the client – if it gets to the client.

The current climate isn’t helping either. “The postal service, FedEx, all shipping is terrible right now,” due to COVID-19, says Clark. “They say they’re at Christmas-level shipping volume, but only have 75-percent employment. Once again, more pressure is on the printer to get things out a day or two earlier so their deadlines will be met.”

Advertisement

Editor’s note:

If you want to share your shipping horror stories, send Adrienne Palmer an email and we’ll cover it in a later issue of Big Picture.

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Blue Print2 weeks ago

Blue Print2 weeks ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago