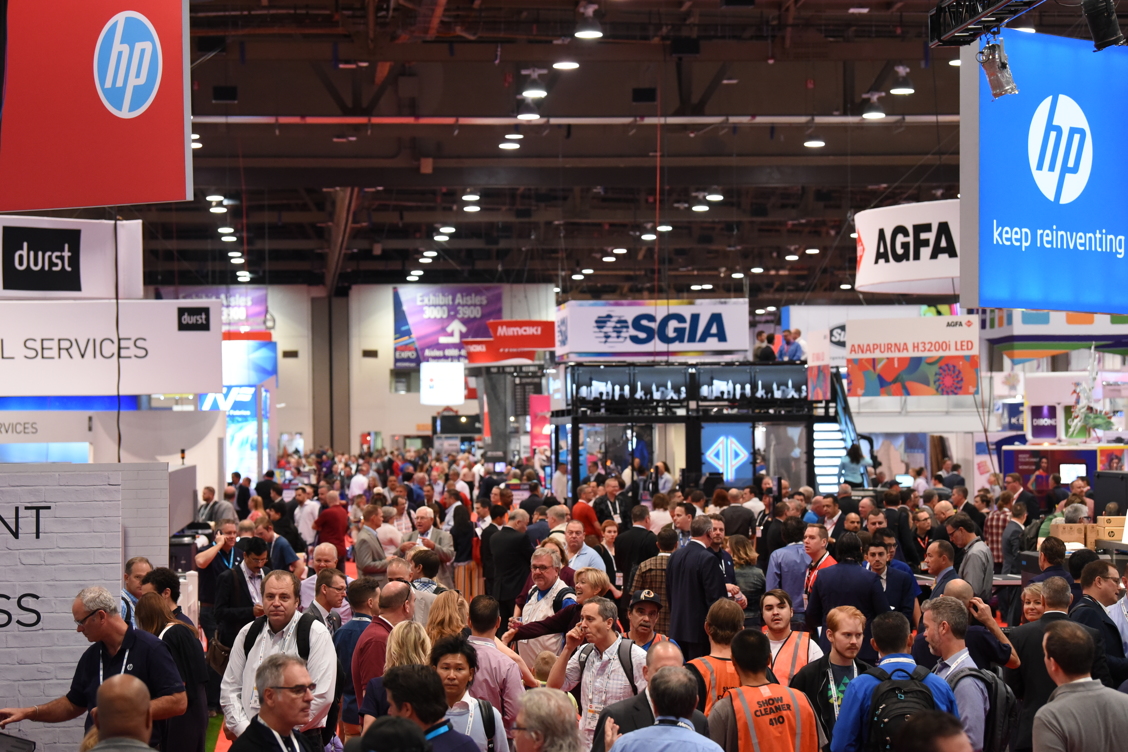

The final iteration of the SGIA Expo drew 24,000 industry pros from around the world to the Las Vegas Convention Center October 18-20. With 612 exhibitors and more than 260,000 square feet of booth space, there was never a dull moment on the show floor or in the myriad education sessions and networking opportunities throughout the event, including Big Picture’s Women in Print Panel and Awards Ceremony.

Liz Logue, senior director of corporate business development at EFI, in a conversation with Big Picture Editor-in-Chief Adrienne Palmer, summed up her current views on the digital print industry: “You either adapt, change, or die.”

While that may seem harsh, Logue makes a valid point. The wide-format printing industry is evolving, and to stay ahead of the competition, PSPs must meet that evolution head on – especially with customers continuing to demand better, faster, and cheaper – and customized – products.

Echoing Logue’s statement, “The signs and graphics market is strong and it’s evolving. It is defining and becoming disruptive. … Print needs to evolve to compete with digital media,” said EFI’s CRO Frank Mallozzi. “It’s not just about short runs; it’s about keeping up with digital technology.”

Adapting to a changing industry means keeping up with, but also exploring what’s new and next. What better place to look toward the future than at a tradeshow? On the show floor, examples of what’s to come were everywhere, from augmented reality to the expanding popularity of printed textiles to methods for automation.

Advertisement

Show, Don’t Tell

Exhibitors focused on showcasing their products’ capabilities in less traditional ways, a trend we’ve seen at recent events. There’s an emphasis on featuring applications – more “here’s what you can create with our printer” and less “here’s our printer’s features.” Creativity was on display in Mimaki’s airline-themed booth complete with a duty-free “shop” featuring their printers’ output; HP’s print-heavy Yesville theme showcased its latex products; and LexJet’s augmented reality, which allowed visitors to have an interactive experience with print. (Check out Big Picture’s use of AR in our October issue.)

Tapping into Textiles

Textiles, soft signage, backlit fabric displays, and wallcoverings were present at booth after booth, from Mimaki and Top Value Fabrics to  Axiom America and Premex Solutions. Interest in digitally printed textiles has been growing, as evidenced by EFI’s acquisition of Reggiani and Matan in 2015, and Gerber Technology’s recent procurement of MCT Digital. Even the bulk of the SGIA Expo graphics directing attendees throughout the exhibit hall were printed soft signage. Digitally printed textiles, silicone edge graphics (SEG), and soft signage have increased in popularity for their reusability, recyclability, and simplified transport and storage. Pigment inks were also a hot topic at the show. Multiple printer manufacturers showcased presses using pigment ink systems for textiles, which would reduce the steps and equipment necessary with other digital textile printing technology such as dye sub.

Axiom America and Premex Solutions. Interest in digitally printed textiles has been growing, as evidenced by EFI’s acquisition of Reggiani and Matan in 2015, and Gerber Technology’s recent procurement of MCT Digital. Even the bulk of the SGIA Expo graphics directing attendees throughout the exhibit hall were printed soft signage. Digitally printed textiles, silicone edge graphics (SEG), and soft signage have increased in popularity for their reusability, recyclability, and simplified transport and storage. Pigment inks were also a hot topic at the show. Multiple printer manufacturers showcased presses using pigment ink systems for textiles, which would reduce the steps and equipment necessary with other digital textile printing technology such as dye sub.

Efficiency Rules

European printers are ahead of the US when it comes to automation, but the US will catch up, said Einar Ek, business development, CAM Global, Esko. While some PSPs embrace automation and workflow software, there are plenty of others who stick with a paper-based system or a more hands-on operation. Making an investment in automation or workflow can often speed up a shop’s production and reduce mistakes.

Meevo is offering a fully automated SEG finishing machine that eliminates the need for sewing specialists, which is often a bottleneck in a shop – or even a reason for some PSPs to avoid working with fabric.

Advertisement

PrintFactory software aims to simplify PSPs’ print workflows by controlling all devices and managing color matching from one central RIP. “The biggest bottleneck for print shops is people,” said Erik Strik, PrintFactory CEO. Workflow software continues to grow in popularity as a way to reduce human error and increase a shop’s efficiency.

“Too many shops are just trying to get by when there are tools available to increase efficiency,” said Michelle Johnson, director of worldwide marketing, SAi. The software company is currently researching augmented reality and artificial intelligence as tools for PSPs to streamline workflow.

With the continued demand for customization and quick turnaround times, PSPs want equipment that can multitask, which is evidenced by the many hybrid presses entering the market each year and software that has a plethora of functions.

Bob Honn, senior director of marketing for Canon Solutions America, said he heard customers repeat the same thing: “What’s niche? What’s new? How can I differentiate my business? I know I have to print banners, that’s the commodity, but what else can I do, how can I generate revenue and save costs too?”

Sustainability in Action

At the “Brands Talking Sustainability” luncheon, panelists emphasized that every company has an opportunity to do something to reduce their environmental impact. While choosing recyclable or sustainably produced substrates is often the first thing that comes to mind in the printing  industry, it’s just the tip of the iceberg. Brian Hite, Image Options, said his shop committed to recycling and was able to reduce its waste from 18,000 tons to 11,000 in a single year, despite doubling facility size during that period. “There isn’t a magic sustainability bullet. It’s about incremental changes that add up,” Hite said. Image Options was also able to reduce its electric bill substantially by switching out the lighting in their facility to LED and purchasing LED printers.

industry, it’s just the tip of the iceberg. Brian Hite, Image Options, said his shop committed to recycling and was able to reduce its waste from 18,000 tons to 11,000 in a single year, despite doubling facility size during that period. “There isn’t a magic sustainability bullet. It’s about incremental changes that add up,” Hite said. Image Options was also able to reduce its electric bill substantially by switching out the lighting in their facility to LED and purchasing LED printers.

Mike Compton, Top Value Fabrics, said shipping fabrics produces a lower carbon footprint. There are opportunities to recycle some materials and search out places like animal shelters, homeless shelters, or schools that will repurpose textiles.

Advertisement

Yalmaz Siddiqui, VP of corporate sustainability for the 90 million square feet of space operated by MGM Resorts, said the PSPs and other suppliers that help MGM identify sustainable products and methods “are the ones that become our go-to.” “It’s a myth that being sustainable is cost prohibitive. There are many choices you can make that don’t cost anything,” he said.

Notable Quotes from the SGIA Expo Show Floor

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Columns2 months ago

Columns2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Blue Print2 weeks ago

Blue Print2 weeks ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Axiom America and Premex Solutions. Interest in digitally printed textiles has been growing, as evidenced by EFI’s acquisition of Reggiani and Matan in 2015, and Gerber Technology’s recent procurement of MCT Digital. Even the bulk of the SGIA Expo graphics directing attendees throughout the exhibit hall were printed soft signage. Digitally printed textiles, silicone edge graphics (SEG), and soft signage have increased in popularity for their reusability, recyclability, and simplified transport and storage. Pigment inks were also a hot topic at the show. Multiple printer manufacturers showcased presses using pigment ink systems for textiles, which would reduce the steps and equipment necessary with other digital textile printing technology such as dye sub.

Axiom America and Premex Solutions. Interest in digitally printed textiles has been growing, as evidenced by EFI’s acquisition of Reggiani and Matan in 2015, and Gerber Technology’s recent procurement of MCT Digital. Even the bulk of the SGIA Expo graphics directing attendees throughout the exhibit hall were printed soft signage. Digitally printed textiles, silicone edge graphics (SEG), and soft signage have increased in popularity for their reusability, recyclability, and simplified transport and storage. Pigment inks were also a hot topic at the show. Multiple printer manufacturers showcased presses using pigment ink systems for textiles, which would reduce the steps and equipment necessary with other digital textile printing technology such as dye sub.  industry, it’s just the tip of the iceberg.

industry, it’s just the tip of the iceberg.