Case Studies

A Package Deal

Digital package printing holds distinct opportunities and challenges.

Published

11 years agoon

If you’ve been evaluating potential profit-center additions for your wide-format digital press, you might need to look no further than packaging prototypes and short-run packaging.

It should come as no surprise that digital technologies have been making some significant inroads when it comes to packaging in the past few years. As research group Smithers Pira (www.smitherspira.com) reports, “digital printing significantly reduces the need for prepress and make-ready, greatly reducing costs, and there is a strong desire among brand owners and retailers for customization and shorter, more targeted press runs.” Smithers Pira projects that digital printing for the packaging market will show compound annual growth rate of 23 percent by 2014 and the overall market is set to be worth $6752 million by next year.

How can shops with wide-format technologies play a role in what seems to be a lucrative market? We asked that question of five companies that are now utilizing wide-format in their own package-printing endeavors:

• Centrix Innovations in North Kansas City, Missouri;

• Mark/Trece, Inc. in Baltimore;

• Create-It Packaging in Arlington Heights, Illinois;

• DiTech Group in York, Pennsylvania; and

• Core Color Graphics in Fallingston, Pennsylvania.

Centrix: Expanding its capabilities

Most print companies in the packaging business add digital capabilities in response to client calls for one-off mockups and short-run specialty containers. Centrix Innovations (centrixkc.com) in North Kansas City, Missouri, has its packaging roots in entirely different arenas.

CEO Marc Radasky launched the company to add a new dimension to his family’s multi-faceted packaging businesses. His grandfather started Columbia Burlap and Bag back in 1950, then followed with Koch Bag and Supply in 1980 to produce poly and plastic bags as well as packing materials.

Advertisement“A couple of years ago, he began looking for opportunities to diversify and branch out from bags into more upscale industrial packaging,” relates Larry Miller, whom Radasky hired as director of operations for Centrix Innovations. “He believed the corrugated business needed a company with short-run capabilities. The larger companies wouldn’t go after clients who wanted to print just 50 displays or pallet wraps.”

Radasky and Miller brought in-house a Durst 750 HS Corrugated Display Printer along with a Zund G3 XL-3200 cutter, and the new Centrix officially opened its doors in January 2013 as a regional supplier to the container companies and converters in Kansas City area. It’s been hitting its mark ever since. “We’ve done a lot of one-offs for prototypes or mockups, but our comfort level is in the 50- to 200-piece short runs,” says Miller.

“Our niche is really where it’s not cost effective to consider die cutting. Digital printing can be an economical alternative for producing as many as 750 pieces. Beyond that, it’s better to think about going to the more traditional printing methods.”

The capabilities of Centrix’s press-and-cutter combination have allowed the company to expand services beyond its original focus. Sixty percent of the shop’s digital production has been packaging; another 15 percent in displays and P-O-P; the rest is in varied types of signage.

“The Durst has given us a really versatile machine for printing on a variety of substrates,” he notes, “and the Zund has proven to be very versatile as well, easy to set up for work we do and materials we work with.”

Although the original intent was to print on corrugated materials, the combination of the press and cutter has allowed Centrix to produce jobs on other media, too: acrylic, banner material, SBS paper board – whatever a client requires, says Miller. He cites that versatility, along with digital’s quick turnarounds, graphic quality and durability, and the ability to print only what’s needed as needed, as all factors contributing to the company’s success.

Advertisement“With traditional printing, it can be weeks just before the dies are cut and the plates are ready,” he elaborates. “But with our digital capabilities, a client can come to us with their art file and have the finished product back to them that day, if that’s what they need.”

By using digital for some customers, Centrix has been able to produce some projects that simply were not budget-feasible with offset. One client, for instance, needed only 40 corrugated pallet wraps for its specialty wines. Centrix printed and assembled large two-piece boxes with full coverage graphics that featured an antique look. “That’s the kind of thing smaller companies just couldn’t afford to do before – and we can make decent money, too,” he notes.

A sporting-goods manufacturer employed Centrix’s digital capabilities for a sales presentation it was making to one of the nation’s largest retail chains. “The retailer wants to see an actual sample of the packaging and how it would look on store shelves. It had to emulate the real thing,” explains Miller. Utilizing the client’s design files, Centrix printed and delivered 10 mockups, 10 more of a revised design two weeks later, then 10 of the final design used in the actual sales pitch.

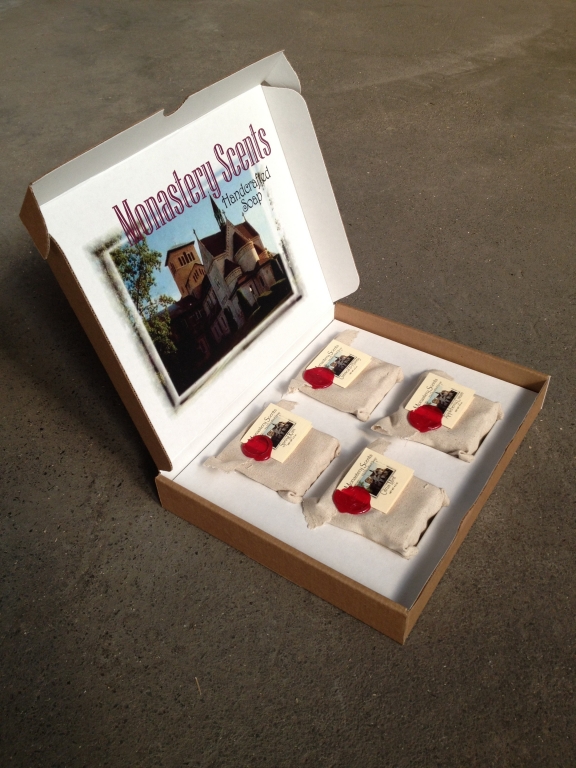

Another example of the shop’s digital work: Centrix now provides affordable multicolor packaging for handmade soap produced by the sisters of Benedictine Monastery in Atchison, Kansas. It’s printed on mottled white paperboard in manageable quantities. “They only have to buy a couple hundred at a time instead of 5000 or 10,000,” notes Miller. “And, we can turn them around pretty quickly, so they order only what they need to fill orders.”

Such projects only broaden the appeal and potential applications for wide-format as a packaging solution. “Digital printing will eventually change the packaging industry,” says Miller.

Mark/Trece: Finding the edge

Since 1962, Mark/Trece, Inc. (www.marktrece.com) has built its reputation by focusing on the diverse needs of the package-printing market. Based in Baltimore, the company includes a network of operations centers in several states plus Puerto Rico. Collectively, the centers provide full-service support to flexographic printers, including: concept development, graphic design, cutting dies, and platemaking.

Nearly two years ago, the company centralized its wide-format digital printing services in its Murfreesboro, Tennessee, facility, under the guidance of plant manager Steve Morris. “We can do prototyping and small runs from 50 to 100 pieces,” he says. “We do a little bit of everything – from mockups to counter units, pallet displays and headers.” The company can also print signs and banners – if that’s what the client requires – but approximately 90 percent of its production is for short-run packaging.

These wide-format output services, as well as cutting and assembly, are delivered with Canon’s Océ Arizona 550 XT flatbed and the companion Océ ProCut 3200 XXL cutting table. The Arizona, allows the company to direct print on a variety of substrates up to 4 x 8 feet and 2-inches thick. About 80 to 90 percent of the shop’s packaging, Morris estimates, is output onto corrugated material, the balance on the client’s choice of chip board, PVC, acrylic, or foam core.

Morris brings 20 years’ experience in display production to Mark/Trece, including 11 years as a plant manager. With that expertise, he’s able to employ the shop’s printer and cutter to bring clients’ packaging concepts to life, whether they require a sample to show their customers, or a custom run for shipping or in-store display.

“This is a little different than everything else our company does, in that we’re actually producing a finished product, rather than the plates or dies to produce one,” notes Morris. “But we feel like this is something we have to offer our customers these days. Digital printing gives us another edge, and it allows them to do some things they couldn’t before.”

As client awareness grows, Mark/Trece is employing the digital services to physically test their packaging concepts, or refine designs and text. Freed of the setup-cost considerations that go with offset flexography, the company is also beginning to take advantage of shorter runs, and quick turnarounds, to cater the message or its look to the specific market area or distribution channel.

“This move was definitely good timing for us,” says Morris, who is confident that demand for these specialty services will only grow.

Create-It Packaging: Lucrative mockups

Brian Lewis, president and founder of Create-It Packaging (www.createitpkg.com) in Arlington Heights, Illinois, hopes that digital printing will eventually allow him to print directly to any substrates. With that goal, he recently added an HP Scitex FB950 flatbed to his mix of printers, which includes Mimaki JV33s, an Epson Stylus Pro 9000, and an Epson SureColor S70670. Also on the roster: a Zund L-3000 and M-1600 cutter, GTK software for registration on the Zunds, and a Thompson clamshell cutter.

“Our nut is really doing mockups,” says Lewis. “With my background in structural design and experience in the packaging industry, that’s really the door opener for us. It gets us in on the ground floor.”

To date, Create-It has produced most of its prototypes and packaging on one of the Mimaki machines. “We bought the newer Epson S70670 for its color gamut,” says Lewis. “It’s a 10-color machine, and it can print metallic.” The Scitex FB950 was brought in primarily to take on point-of-purchase production.

Currently, mockups are typically printed to adhesive-backed vinyl on one of the Mimakis, then mounted to paperboard for transformation into a three-dimensional package. But, says Lewis, “My ultimate goal is to no longer print on vinyl, but to print directly on whatever material the client requires,” he says. “When you print on a 3-mil vinyl, then apply that to a 12 point board, you end up with something that feels like a piece of plastic.”

So the Scitex FB950 apparently will be put to use here as well. In the few months since its installation, the HP flatbed has also generated some new opportunities. “We’ve done some good short runs with it,” printing directly to cardboard, corrugated and foam core,” he reports.

Create-It’s clients include brand managers, creative directors, and marketing teams eager to bring consumer packaged goods to retail. “We do a lot of mockups, salesmen’s samples, and retail planograms,” he says. “In the past, the business was definitely a lot more ‘onesies’ and ‘twosies,’ but now we’re starting to do more actual packaging for products. The quantities are starting to get bigger and bigger.”

The JV33’s white-ink capability has allowed clients more creative options in their designs, says Lewis. “White ink has really changed our company,” he reports. He’s utilizing it to print on other materials, well beyond the realm of the folded carton. “We’re finding other media [for it] and we’re now printing on foil and clear films,” for flexible prototypes that can adhere to the shape of a product or bottle, he says.

Lewis advises others who may be considering packaging as an application for the wide-format presses to move cautiously: “Anybody with a digital printer can do a mockup once in a while, but you’ve got to have the design background to take someone’s concept and turn it into a produceable piece,” he asserts. “If you want to do this, you need a structural designer on staff, someone who understands how the packaging industry works.”

DiTech Group: Success in short runs

Together, the member companies of DiTech Group (ditechonline.com) provide the flexographic package printing industry with design, engineering, and the manufacturing of die-cutting tools and flexography printing plates. But the company’s DiTech York division – via its York Steel Rules affiliate in York, Pennsylvania – has expanded into actual packaging production, utilizing a wide-format digital flatbed press. It’s printing for some customers directly, others as a wholesale print partner.

“Most converters are staying away from the short runs, and they’re able to use our capabilities if that’s what their customers require,” observes president Jim Osmolinksi.

DiTech’s digital services were launched seven years ago with the purchase of a Gandinnovatons Jeti 3040, as an experiment in direct printing to substrates in limited quantities. Demand steadily grew, prompting Osmolinksi to upgrade his digital capabilities last year. “We had reached a point where we were getting a lot of requests for mockups to assist our customers in the packaging business,” he explains.

Osmolinksi ended up investing in Agfa’s upgraded Titan Jeti 3020 UV flatbed. With its white-ink capabilities and maximum print area of 6.5 x 10-feet on media up to 2-inches thick, the Titan is now his primary production unit, he reports. Demand has followed in unexpected ways.

“We began doing a lot of mockups, but it quickly turned into being used for printing finished products, in runs up to 1000,” says Osmolinksi. Production, he estimates, is now running around 4 percent in prototypes; between 50- and 60-percent finished packaging; and the rest in displays, pallet wraps, and signage.

Demand for mockups has evolved, too. “That’s expanded from one or two pieces to someone ordering 10 pieces because they are going to make a sales presentation.”

Clients, he believes, are responding to some distinct advantages of digital printing: “The biggest thing is they can get a mockup quickly and cheaply, and the quality is good,” he notes. “And, if they want to make changes to the design, they can do so easily, and actually see how it’s going to look as a finished product.”

There’s an economical advantage, too, when the order is only for a few hundred pieces. “They don’t need to spend $4000 just for the dies and plates,” before production can begin.

For all these reasons, Osmolinksi considers digital printing a good fit for his company and its customers.

“The only limitations to digital so far seem to be producing packaging in large volumes,” he says. “It started for us as an investment in becoming more of a full-service provider to our clients and it’s allowed us to capitalize on those relationships in other areas, as well.”

Core Color Graphics: A label approach

Core Color Graphics (www.corecolorgraphics.com) strives to be a “complete graphics solutions provider” of everything from interactive website development through wide-format printing, according to CEO Thom Urban. In fulfilling that mission, five years ago he purchased a Roland VersaUV LEC-300 UV printer/cutter for his Fallingston, Pennsylvania, company.

“It’s allowed us to provide our customers with some unique products, and to do some R&D on prototypes that we’ve been able to turn into a real service,” he says.

Core Color has used the printer for prototype printing on holographic films; printing and cutting custom-designed skins for iPhones and other mobile devices; even printing graphics on a polycarbonate film for installation behind video touch screens. “It takes our business in a lot of new directions and allows us to offer more types of products to our clients,” he says.

The Roland has also been used to first test, then produce personalized packaging for boxes and pouches for what he describes as a “high-end jewelry company.” Graphics were printed, then cut in quantity on the LEC-300, the art and lettering knocked out, and used as stencils for airbrushing each personalized package.

The LEC-300 is also employed to transform ordinary bottles and cartons with eye-catching labels and graphics. “It prints with a texture” notes Urban. “If I print a label with a wood grain, I can make it look and feel like a wood grain. There’s no other way a small company could have a label like this if they only need a few hundred – it would just be too expensive.”

Blackwoods Hot Sauce, a specialty brand of condiments, tapped this capability to help make its Blackwood Premium Wing Sauce shout from the shelves. Core Color utilized its Roland VersaUV LEC-300 UV to print 800 of the cut labels, with a textured effect, onto a 3.8-mil cast air-egress vinyl. “We do a lot of labels, a lot of barcodes, and can get as many as 250 on a sheet at a time,” Urban notes.

Other print providers have also sourced Core Color for their own prototyping needs. For instance, an area flexographic printer provided Core Color with its design files, and the boards for printing, before committing to a full, high volume production run. “We’ve done from one to as many as 100 of the same design,” explains Urban. “Sometimes the customer just needs to give his clients a sample for them to look at. Other times, they need to put together a whole planogram to show how their packaging will look in a store and fit on shelves.”

SPONSORED VIDEO

Printvinyl Scored Print Media

New Printvinyl Scored wide-format print media features an easy-to-remove scored liner for creating decals, product stickers, packaging labels, and more. The precision-scored liner, with a 1.25” spacing on a 60” roll, guarantees a seamless and hassle-free removal process.

You may like

Check Your KPIs, Reach Out to 200 Top Customers, and More To-Dos for Print Managers in May-June

National Moving Month, Selfie Day and More Business-Generating Events for May and June

Drupa Seminars to Look at the Potential of Artificial Intelligence in Printing and Imaging

This Wide-Format Pro Started at Age 11, and 32 Years Later, Still Loves What He’s Doing

Wide-Format Printers Share Their Thoughts on Business-Advice Books

3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

SUBSCRIBE

Bulletins

Get the most important news and business ideas from Big Picture magazine's news bulletin.

Most Popular

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoHere Are the Winners of the 2024 Best of Wide Format Awards

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

-

Blue Print3 weeks ago

Blue Print3 weeks agoThis Wide-Format Pro Started at Age 11, and 32 Years Later, Still Loves What He’s Doing

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoPrivate Customer’s Bespoke Bathroom Wallcovering Showcases Their Passions

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoColorado Town Hypes Its Incredible Natural Gifts in City Hall Rotunda Project

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoIllinois Print Pros Help Historic Toy Brand Create a Memorable Shopping Environment

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoIconic Music Venue Celebrates Half-Century With Vibrant Exhibit of Rock Artifacts

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoCalifornia Forest Firefighters Use Dynamic Car Wraps to Recruit New Members