BRIAN HITE, PRINCIPAL/COFOUNDER of Image Options in Lake Forest, California, and Pam Richards, owner of Color Gamut Digital Imaging in Las Vegas, highlight best practices, challenges, and opportunities in soft signage. Watch the video, originally shown at ISA’s The Link…Soft Signage–Virtual event, at bigpicture.net/videos.

Adrienne Palmer: Offering soft signage has its fair share of benefits, including sustainability, shipping costs, and ease of installation and removal. Let’s talk about these advantages, specifically in your shops.soft signage

Brian Hite: We were in soft signage back when Image Options first started in 2000. We did it as a differentiator from what was available in traditional vinyl banners and in regular photographic type prints, both of which we also did. Over time, we’ve continued to remain in the fabric business. Each time a new technology would come out, we would evaluate that technology, and add it to our offerings. Currently, we’re running both direct and indirect dye sublimation all the way up to five meters. It’s been great for us – the weight savings, the shipping, being able to ship in a smaller package to reduce cost, and ease of handling.

Pam Richards: We didn’t get into the soft signage part of the business until much later, in 2015. It took us a while to figure out what was best for our industry. Obviously, speed – everybody wants to be faster – so we looked at many different options. When we first started, printing direct was the way to go. Everybody thought printing direct would eliminate a lot of time, but the quality wasn’t there. So, we picked a three-meter and a five-meter thinking that would help us get a leg up, because we could be one of the very few in the five-meter application. Unfortunately, there wasn’t a lot of material at that time. But it turned out to be very, very good for the tradeshow side of the business. There are so many different things you can do with soft signage where you’re limited when you’re printing rigid.

AP: What are the top applications your clients are asking for in your specific markets?

PR: In our situation, it’s SEG. It’s an easy application where they sew a beading onto it. We do have a lot of applications where they’re doing away with vinyl, and they’re going to cloth, obviously for sustainability purposes, where we just put a pocket in it, but the pillowcases and the SEGs are our primary selling points.

Advertisement

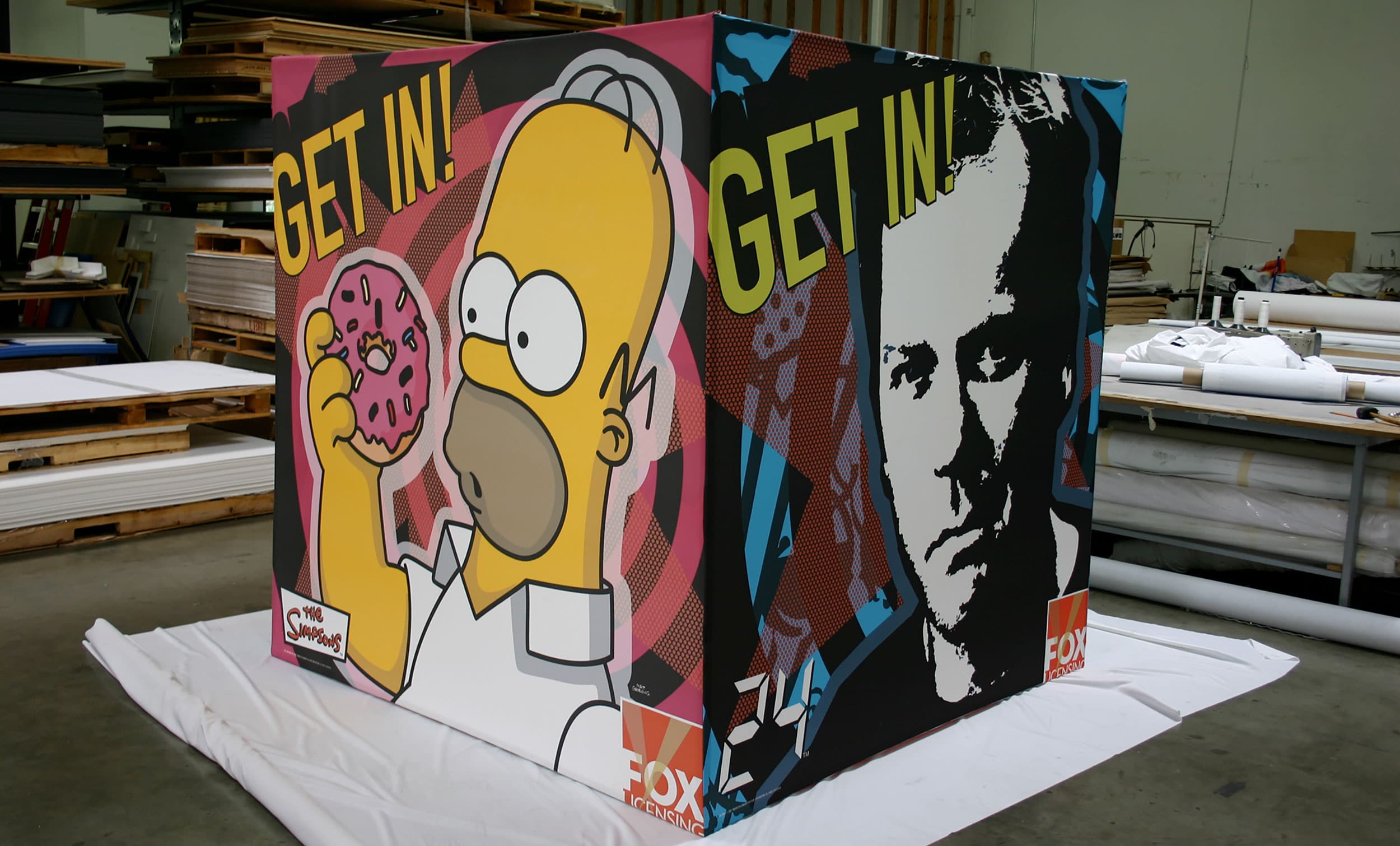

BH: We do a lot of SEG, both for tradeshow and retail. A lot of the tradeshow work is tension structures. So, we’re producing a lot of fabric-wrapped aluminum frames. We’ve done some that have been 600 to 700 feet long and 1415 feet tall. If you were to use another product, like vinyl, you’re probably looking at 15,000 pounds of product. And when you’re talking about hanging it from a ceiling and within a convention center, you can use fewer pick points, which saves the client money. The material is easier to handle, it’s more compressible than vinyl. So, predominantly, if you’re in the event and exhibits industry, it’s tension structures in SEG. If you’re in retail, it’s almost exclusively SEG, whether it’s backlit or opaque.

AP: How often are you installing for your customers vs shipping materials and instructions?

BH: If it’s the first time it’s being installed and the frames are being mounted, we would likely do that. Install refreshes are typically taken care of by the store personnel.

PR: We’ve put a lot of different ideas into place where now everything gets fitted before it goes out the door and pictures get taken so we know it does fit. Now we get less calls than we ever got before.

AP: What are your tips for print service providers who are looking to add soft signage?

PR: Don’t give up. It’s not an easy application. And there are more things involved. Rather than just buying a printer, you need to buy a sublimator and cutting machines – you need to have a full sewing department that understands the application. So, there are steps involved in each process. The soft signage part of the business, it’s a learning curve. The temperature, and humidity is a big factor. In Nevada we have zero humidity. So, we have humidifiers that are mounted on the walls of both our rigid and roll-to-roll as well as our soft signage side of the business so that it keeps the dust down and keeps the machines happy.

Advertisement

BH: If you’re going to get into the business you need to realize that what you think you’re going to spend, you’re probably going to spend more just because of finishing and sewing aspects. So, reach out to the equipment manufacturers for cost of ownership of the equipment, resolution of the equipment, and what the costs are. Get them to demonstrate how it handles material, how the materials are loaded, etc. The transfer process is probably the easiest to train. But even that has its own set of criteria that make it difficult. With temperature ranges, you’ve got to constantly monitor thesoft signage temperatures on your presses. Because you know, 385 degrees yellow is one color, but 390 degrees yellow is a different color. So, the color management side of making sure that what you’re putting on the fabric is accurate is another huge aspect of producing good quality graphics. At end of the day, you can be the best printer in the world with the best equipment in the world, but if you don’t devote the resources to the finishing side of the business, that’s where you’re going to fail. So really, really focus on that.

PR: Do what you can to get the manufacturer to give you the training for the operation side. Take some classes in color so you understand the color, and make sure you have the proper equipment for profiling the color. There are a lot of resources for training, how to sell. It’s getting that basic equipment operation down first, and then going through and making sure your machines are set up. Fortunately, a lot of the sewing equipment now has computer controlled tension on the thread. Get your list together and ask somebody who knows, “Hey, do I have everything I need on this list? Or do I have to add a few more things? Or is anything on here I don’t need?”

BH: Everybody that’s out there, they’re willing to help. There’s a whole group of people who are willing to give advice. Fabric manufacturers are motivated to help because they want to sell you media so they will share whatever they can. Equipment manufacturers, the same thing, they want to sell you their machine, so they are going to contribute, but you have to take everything with a grain of salt and say, “Why your machine and not their machine? I’ve looked at their machine I really like it. What makes yours different?”

PR: It’s not an easy application to start, but never give up. It’s worth the challenge. It really is because there are so many benefits to soft signage. You learn from your mistakes, and if you have a good team in place that’s willing to drive you, the outcome is excellent.

PHOTO GALLERY (15 IMAGES)

VEHICLE WRAPS + GRAPHICS3 weeks ago

VEHICLE WRAPS + GRAPHICS3 weeks ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Case Studies3 weeks ago

Case Studies3 weeks ago

Case Studies1 week ago

Case Studies1 week ago

Benchmarks3 weeks ago

Benchmarks3 weeks ago

Press Releases2 months ago

Press Releases2 months ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Press Releases2 months ago

Press Releases2 months ago