HD Walls and Olivia Capuano

of Olivia Jane Design

“HD Walls has always had a focused approach in commercial wallcoverings geared toward the hospitality industry and toll printing for partners,” says Emily Carretta, designer, HD Walls – a custom digital and gravure printer specializing in meticulously crafted wallcoverings and design. “Many of our clients find us because of our experience with metallic and specialty materials that aren’t as commonplace in the digital industry.” Olivia Jane Design is one of those clients. The full-service interior design firm is dedicated to the creation of hospitality and residential spaces that are transportive and deeply moving, according to its site. “I have worked with HD Walls many times before, and Emily specifically. She has been a great resource,” says Olivia Capuano, designer and founder, Olivia Jane Design. “I’ve incorporated digital printing in several design projects throughout my career, from restaurants and nightclubs to healthcare, to create custom vinyl wall and ceiling coverings.”

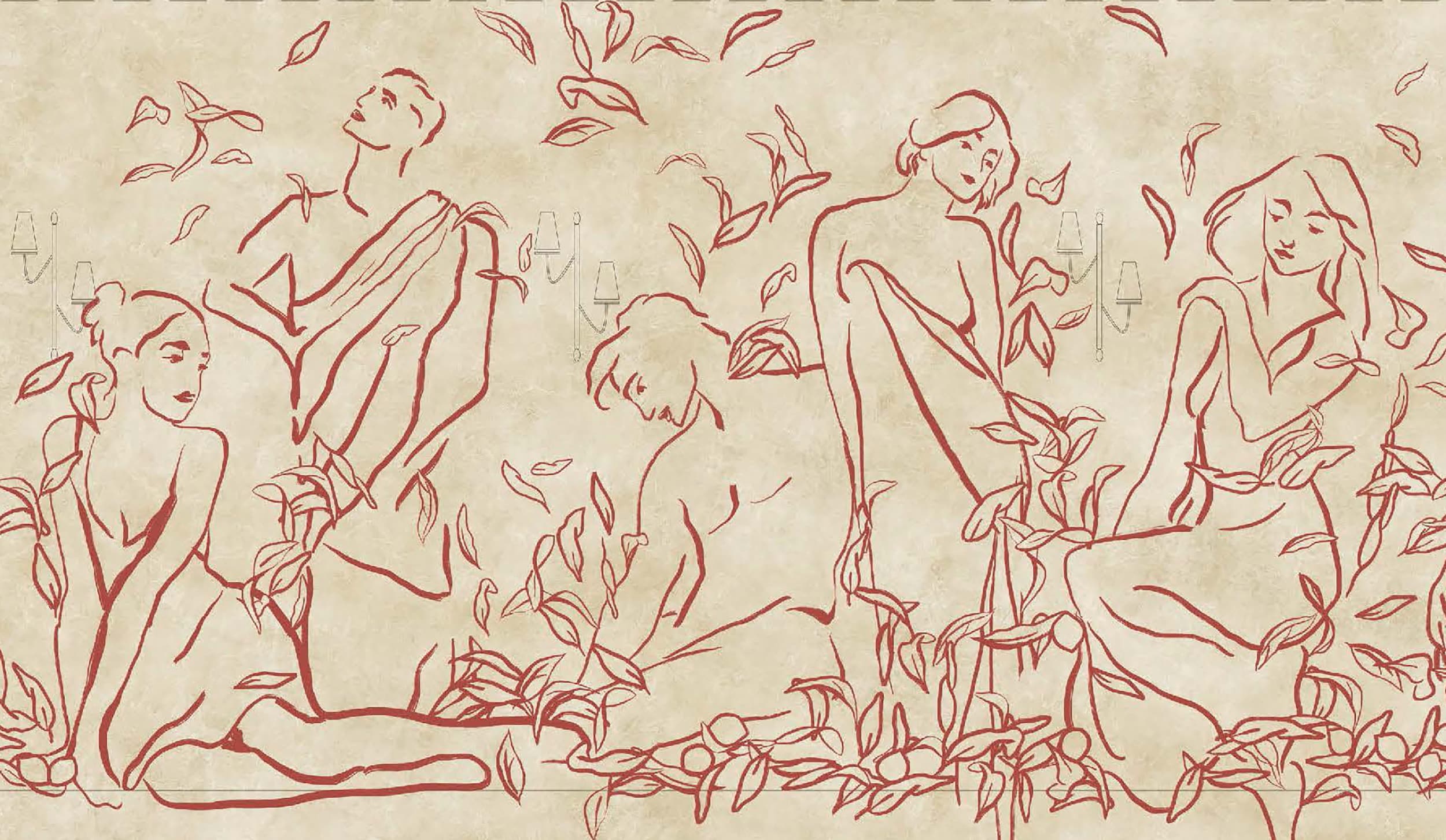

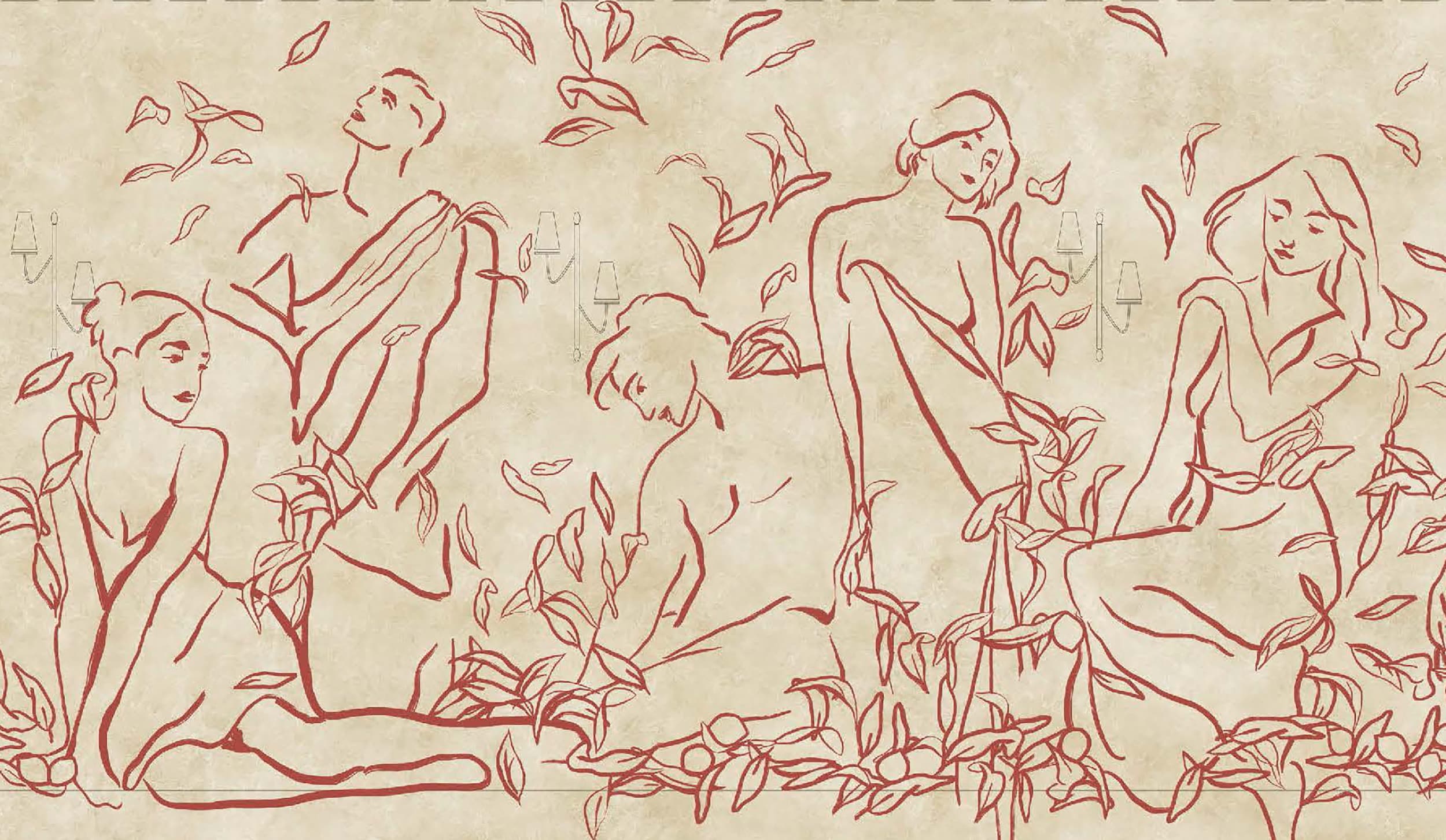

Capuano and Carretta recently partnered on a project for Amalfi, a Bobby Flay restaurant in Caesar’s Palace in Las Vegas. The companies worked together on the digitally printed wallcoverings wrapping the private dining room of the Mediterranean-inspired restaurant.

“I reached out to Emily regarding this space after we had to value engineer the design of these walls from a plaster mural to a digital print. We started off with concept imagery for the look and feel and got right into the design,” says Capuano. “Once we nailed down the artwork, we positioned it on the elevations of the room around doorways and openings. We then went back and forth several times on the background and linework colors and printed six to seven samples, showing a minimized overall and a partial full-scale portion.”

“We really strive to honor the designer’s vision and share our knowledge of materials, print techniques, and installation, so we can build the most perfect design solution together,” says Carretta.

“DreamScape has made our job easy by offering a wide variety of base materials, as well.” HD Walls printed the graphics via its EFI Vutek 3r+ LED roll-to-roll printer onto DreamScape 20-ounce Plaster wallcovering material.

“I am thrilled with the result. The illustration is full of life and movement without being overpowering, and it gives the enveloping feel of a mural with all the benefits of a digital print,” says Capuano.

When working with print service providers, Capuano is looking for “quality of printing; durability – often these are being installed in high-traffic environments and need to withstand wear and tear; a variety of substrates to test on – depending on the business of the pattern or the lighting where it’s being installed, you can play with texture and reflectivity; and full scale strike-offs for approval – it helps immensely to see a portion of the installation at 1:1 scale to get a sense of how it will feel in the space.”

Carretta is one of four in-house designers who are skilled in graphics, pattern creation, color, and layout at HD Walls. She says having a capable design staff is critical for PSPs looking to enter this market. “Every project requires front-end design, and it can be a long process of edits,” she says. “What we really try to do is preserve the beauty of the traditional printing processes and preserve the artist’s hand, while using new technologies to amplify the aesthetics of wallcoverings. We value artists and designers, and I think that value resonates in our work.”

The wallcoverings in Amalfi were designed by Olivia Capuano and printed via HD Walls’ EFI Vutel 3r+ LED roll-to-roll printer.

Finding designers who value digital print is also key. Capuano and her team see the benefits. “You get a product that’s completely unique. You’re able to customize the print/pattern/colors to adhere to your design or brand identity,” she says. “Low cost and short production/installation time are always at the top of the list for hospitality projects. It gives the effect of a hand-painted, fresco mural without the artist fees and extensive on-site install time required. Durability is also a consideration; Type II Vinyl Substrates are great for commercial applications.”

Western Sensibility

and Leana Becker

Western Sensibility is a digital textile printing studio specializing in sustainable, life-friendly textiles inspired by the American west. “Western Sensibility was built to redefine interior spaces in thoughtful and sustainable ways. We never looked at interiors as a way to diversify our market offerings, but rather we looked at interiors as the market we wanted to serve,” says Kathryn (Katy) Sanders, founder and CEO. Their clients range from high-end interior design firms to privately owned restaurants and businesses that “want to take a boutique approach to designing their spaces. We develop projects for the residential, hospitality, and commercial segments and create unique solutions for each category.” Their newest hire is Leana Becker, former director of Interior Design for Kelly Wearstler, an American designer for high-end residential, commercial, retail, and hospitality spaces. As Chief Creative Officer at Western Sensibility, Becker’s focus is to develop the Missoula, Montana-based print shop’s growing roster of interior design clients and bespoke white label projects.

Becker is no stranger to luxury interior design or digital textile printing. She sees customization has a huge advantage compared to other print methods. “It doesn’t get any better than creating something original or working with an artist to have something personal and specific for your project.”

Advertisement

Custom wallcovering completed for a Missoula, Montana, restaurant using an Epson SureColor F9470 dye sub printer.

When partnering with printers, like Sanders, Becker is looking for quality and reliability. “I have to feel confident that my printer has my back. There is a craftsmanship to printing and bringing to life someone’s artistic vision in the way that meets or exceeds their expectations.” Becker has so much trust in Sanders and her team, she has yet to be present for the print production. “I’ve received some photos during the process, which is very exciting. I realize there’s more to this story on the printing end, but that’s where the faith and reliability come in,” she says. “I’m confident Katy knows what to do and it makes everything easier. How many times can you hand something over and the other person just knows what to do? It’s such a relief so I can focus on what I need to do.”

“When it comes to working with designers, building a relationship is everything,” says Sanders. “It’s not as contractual of a workflow as it may be when printing marketing graphics. It’s important to collaborate and show them you’re their true partner by understanding who they are and what their goals are.” Material selections are key in the interiors market. “The right or wrong selection could make or break a project. Do your testing (lightfastness, crocking, flame repel, etc.) and work with the purchasing agent to get the proper certifications to ensure a smooth outcome.

Becker recently needed to print a headboard fabric for a boutique hotel project. “It was important that the color matched the hues in the companion wallcovering,” she says. The pattern artwork was done by an artist and delivered via Adobe Photoshop. “We had the print railroaded to avoid any visible seams once the headboard was upholstered. We did one print test with Katy on two different base cloth options. We selected the Crosshatch Slub both for its texture and the inherent flame repel. We also adjusted the scale of the artwork before the final printing. It came out beautifully.”

Becker has also created a namesake collection of patterns with Sanders. “I love pushing the traditional boundaries of common patterns like stripes, florals, plaids, etc. by taking advantage of the medium. Photorealism, transparencies, gradients, full-width repeats – it sounds technical, but you can add so much depth and texture that you couldn’t do before. There are no restraints. We did print tests of all the proposed patterns, and I chose my favorites. We tweaked the colors in one more round of testing and that was it. We even did a custom color of the Ripple pattern for a restaurant project in Missoula.” Western Sensibility used its Epson SureColor F9470 dye sublimation inkjet printer onto inherent flame-repel, life-friendly Crosshatch Slub textile for the Brasserie Porte Rouge restaurant. “This is actually a very interesting case because it’s a print but reads as a solid,” says Sanders. “It’s a beautiful example of how prints can be incorporated in an already colorfully complex environment.”

Sanders is a third-generation textile printer. She knows the positive impact digital print can make on the interior design space. When asked how to find designers who value digital print, she replied: “Who doesn’t value digital print? If a designer doesn’t value digital print, then they’re probably not familiar with the evolution of the technology. If that’s the case, more than likely they’re referencing a digital sample from a decade ago – this is your opportunity to show them how far our industry has come!”

If you’re not well-versed in this market, “Do your research and get into a design center as soon as you can,” says Sanders. “Though it’s still digital textile printing, the interiors market is much more tactile than signage, for example. Quality is everything and I recommend starting in a specific geographical or product niche.”

Arizona Fashion Source

and Gwan Yip of Core 3D

Arizona Fashion Source is changing the way digital print is accessible to designers. “We support hundreds of creators (designers) who were unable to print what they wanted on their fabrics without having to meet large minimums or being stuck to mostly poly blends,” says Sherri Barry, owner of the full-service fashion design, apparel development, and manufacturing company. The multi-line apparel manufacturer offers on-demand (sell it, make it, ship it) and traditional manufacturing options with low minimal order quantities (MOQs), according to its site. The company has a diverse client base of emerging brands/apparel entrepreneurs, inventors, big brands, ecommerce sites, interior designers, digital artists, artists, and more.

Fabric Tempe is Arizona Fashion Source’s resource partner. It provides the resources emerging designers and brands need to grow and thrive, according to its site. The combined services include fashion education, design, product development, and pre-production services including patterns, tech packs, samples, fittings, pattern revisions, digitizing, grading, markers, and cut-and-sew options. “Most all creators truly value and want creative license for print design, along with their fashion designs. Now they have a way to do it,” says Barry.

Core 3D develops custom, high-quality print designs and garments for the crypto community as both physical and digital twins.

Arizona Fashion Sources provides an online education platform for designers to learn about the decisions they need to make to ensure a successful product. “We teach them how to be their own production manager and do their own quality control,” says Barry. “We offer scholarships to 250 designers per year to receive this education for free, or at a highly discounted rate depending on economic need, through the 501(c)(3) nonprofit I chair and co-founded, Fabric Tempe (fabricincubator.com).” To ensure a successful partnership, as a PSP, “you need technical design and graphic design experts and the right CAD software and workflow software to support engineering the prints/ideas the clients provide,” she says. “This allows the ability to send the print files into production and have the final product come out exactly the way client wanted it to look.”

Just three months ago, Gwan Yip, CEO of Core 3D, didn’t even know this technology existed. “After producing our first NFT digital and physical apparel collection earlier in the year using traditional techniques I thought, ‘There has to be a better way,’” he says. He connected with Barry via a contact at Lectra after visiting its Innovation Center in New York City. “We’ve only completed one full collection from Cryptpal, an up-and-coming native Web3 fashion designer, but we have six more collections from NFT projects in pre-production due to launch over the next few months.”

Advertisement

Arizona Fashion Source uses its Kornit Presto printer with other clients, like Cryptees and Adea Everyday Luxury. “It’s all we need because it’s so versatile,” says Barry.

The collection for Cryptpal included a hoodie and sweatpants for two separate events. “This job was especially challenging because we only had four weeks to design, produce, and ship the order. Fortunately, we’ve been working with Sherri’s team over the past few months to integrate our 3D design platform, Core3D, and AFS. So, Cryptpal was able to design and sign off on the design in a few days,” says Yip. The team used Arizona Fashion Source’s Kornit Presto for direct-fabric (DTF) printing. “The design was converted into the necessary print files, produced in a few weeks, and was able to hit the deadline in the nick of time. This has given us confidence in our ability to scale with Sherri and Arizona Fashion Source whilst meeting the pace of the Web3 and NFT market.”

Now that Yip has had a taste of digital textile printing, he knows what to look for: quality, accuracy, and speed. “Due to the fast-moving nature of the Web3 and NFT space, all three are paramount for us when working with print service providers,” he says. “The market is flooded with traditional ‘merch’ quality products and we’re on a mission to demonstrate what high-end apparel designs look and feel like in Web3.”

He also understands the benefits. “There’s flexibility in what can be produced, which unlocks creativity on a design layer,” Yip. “One of the most common complaints our customers have before working with us is they’re limited in what traditional merch companies can do, primarily through screen printing. Once they see what’s possible with digital print they start to believe ‘merch’ can be so much more. The other huge benefit is how Arizona Fashion Source/Sherri has gone all in on the concept of on-demand manufacturing through digital printing. I was fortunate enough to visit the factory last month and was blown away at what her team can do.”

PHOTO GALLERY (21 IMAGES)

VEHICLE WRAPS + GRAPHICS3 weeks ago

VEHICLE WRAPS + GRAPHICS3 weeks ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Case Studies3 weeks ago

Case Studies3 weeks ago

Case Studies1 week ago

Case Studies1 week ago

Benchmarks3 weeks ago

Benchmarks3 weeks ago

Press Releases2 months ago

Press Releases2 months ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Press Releases2 months ago

Press Releases2 months ago