UR SIGN AND DISPLAY graphics industry is mainly dealing with the print production of huge or small billboards, posters, pop-up displays, soft-signage, and many other appealing commercial images. We’ve been working with retail and we sell our rhetoric of marketing image on a daily basis.

UR SIGN AND DISPLAY graphics industry is mainly dealing with the print production of huge or small billboards, posters, pop-up displays, soft-signage, and many other appealing commercial images. We’ve been working with retail and we sell our rhetoric of marketing image on a daily basis.

What we tend to forget is that we, the sign and display people of the world, are only a small part of the total printing industry. We’ve seen print always as an individual engagement with the surroundings of promoting a product or service. We print what we get, we don’t design, we don’t create, we just print. I’ve been active in this world for many years. The place where resolution, color, and substrates are the main topics, not the design nor the message behind the design. Yes, we love to talk about technology and how to offer solutions, but besides the discussions of how much adhesion there is on Plexiglas sheets or how we can improve our color constancy, our industry sometimes just prints.

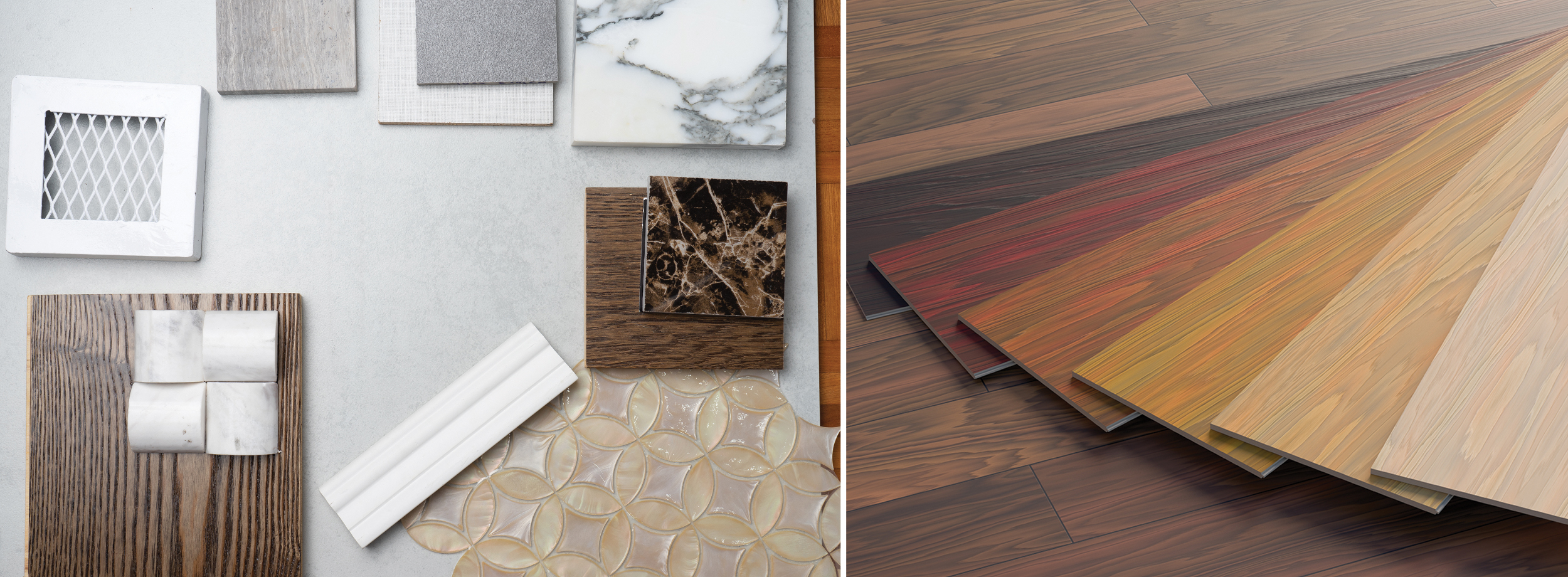

I now have a different view on the world of print. Surfaces is the name, not print, not CMYK, nor the role of web-to-print. Surfaces are all around us and have a great impact on our lives. The décor design is the focal point, not the print technology. The haptic, the feeling, and the view are the important things in life.

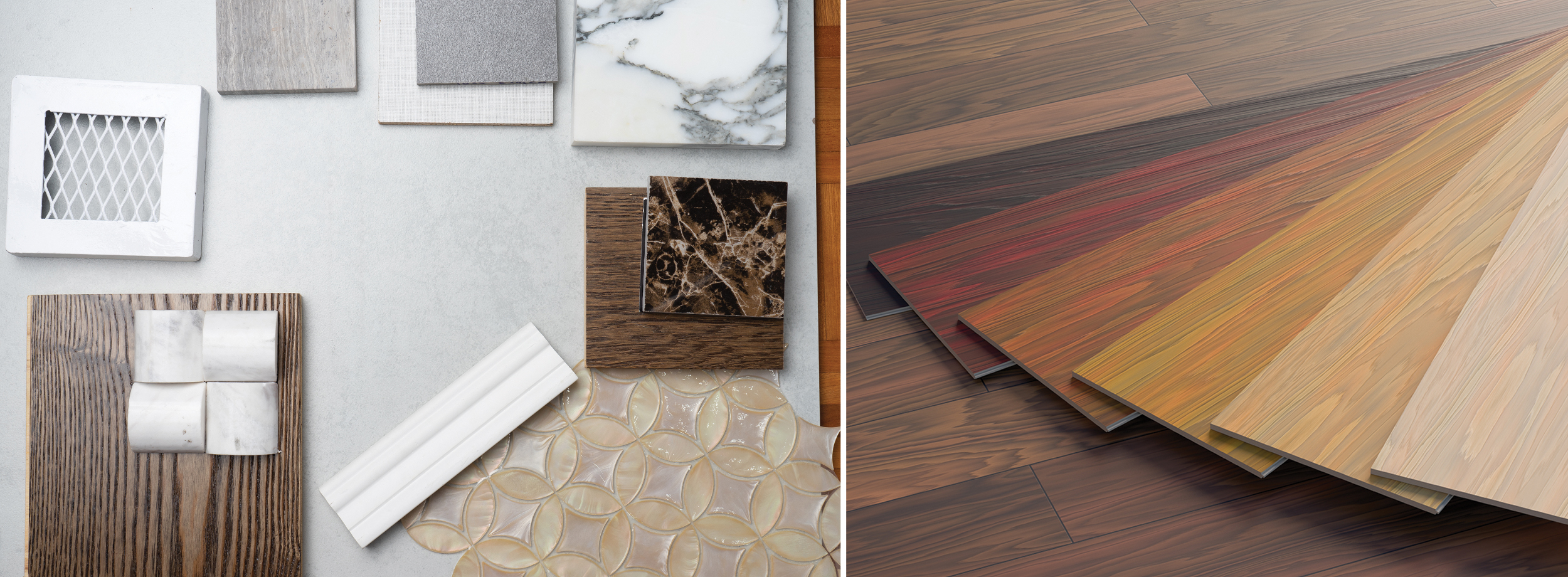

So what are surfaces? The term is used for all kinds of applications, like flooring, furniture, in and outside cladding, kitchen workbenches, and bathroom walls. The key word is “applications,” which is the correct approach to selling décor and the coming-home feeling. Trying to reproduce the natural colors of woodgrain and stone, understanding people’s feelings when they touch the surface and how they experience the surroundings are the main challenges in the surfaces industry. This is definitely not the same as printing a graphic image – the complexity of the surfaces market is also a lot bigger.

Although this market is enormous, it’s still mostly printed with analog gravure printing technologies. Yes, printing in billions of square feet. In this industry, they don’t talk about square feet but in tones. The advantages of printing in roto-gravure are simple; it’s relatively easy if you know how, it’s cheap, color-kitchen based, and constant in quality. The disadvantages are as big as the advantages: multiple expensive gravure cylinders are needed for each design, the separations for gravure cylinders are complex, setup cost is per décor, and the change of a design is a time-consuming and expensive exercise. Here’s where digital could come in to replace some of the gravure-based systems in the market. The reason for digitalization is the consumer is starting to demand bespoke designs for not only table tops but also flooring and wallcoverings. Hotels and restaurant chains want to convey their own identity; they’re looking for new ways to get their brand in the customer’s face. With current digital printing technology, we can help this new industry. Our color system is CMYK-based, so we have 16 million different colors in our gamut. We can print any design and we can switch designs on the fly. The perfect storm against gravure printing, right?

Well, all that is true, but the coloration in the surfaces world is very different. The use of graphic CMYK inks would result in low-gamut quality images of wood grain or create metamerisms. This is a phenomenon where the colors of two objects appear the same under a particular light source but actually have different spectral energy distributions. When a different kind of light source is used, the color difference between them is revealed. So, we have no experience in the graphics world when we start looking at the image in different lighting conditions. Yes, we know that color is influenced by light and that bidirectional banding is created because of the reflection of light. But think of the top of your desk and the edge of the same desk. Or, if you’re laying down a laminate in your children’s bedroom, the direction of your woodgrain determines the color shifts, right? No, the surfaces industry has solved this with the correct usage of pigment colors.

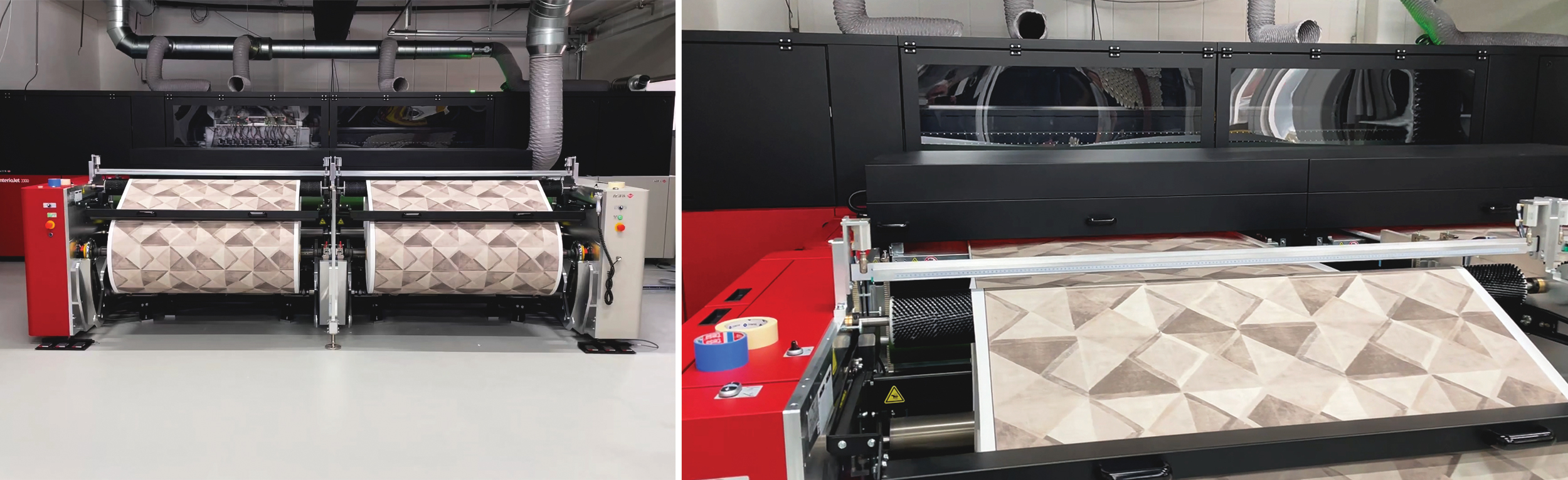

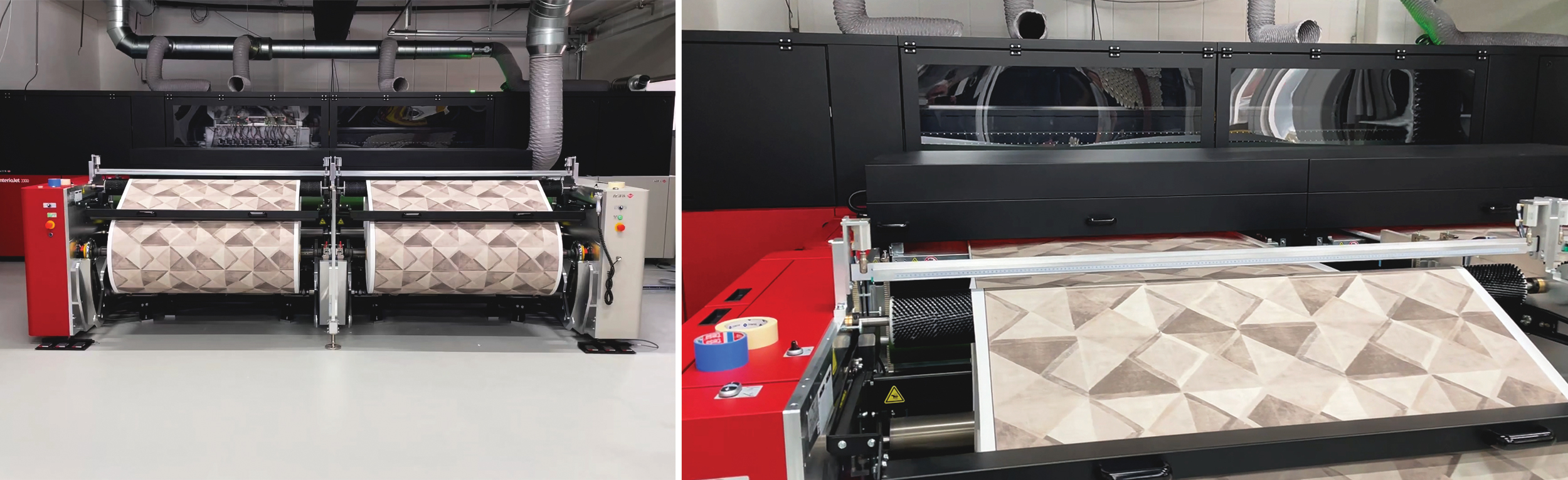

Digital printing allows for a myriad of applications in nearly every market segment. Photos courtesy of Chiyoda Europe NV.

So, the result of all this great technology is that our current graphic printers are not suitable for this industry. Well, that’s not totally true because if we change the inks and the way we print we can get the same results as gravure and we could conform to these new industry standards. Before the industry started developing these inks and printers they teamed up with companies like UNLIN or part of the Mohawk group, both leading manufacturers of flooring. The partnership and the co-development of some of the features gave companies an advantage to understand the market better and solve some of the problems at hand.

After years of testing and researching, they started the development of specialty inks for the flooring and surfaces industry. Some companies found that if you used the same pigment colors as gravure it would be possible to get the same results as or even better than traditional printing technologies. The introduction of a special patented red ink and a new light black ink made it possible. Printing digitally has now become viable for the surfaces industry. This printing technology is usable for printing on surfaces and on substrates, so we have the best of both worlds.

On the other hand, I realized that flooring companies aren’t really interested in printing on a wood chipboard or any hard surface directly – this is not what they do in this industry. They want to print on a special paper that can later be impregnated with a melamine resin and then pressed together to make a strong sandwich-like print. Think about four to five layers, a top ware coat, the printed impregnated paper, and some Kraft sheets to make the package workable. This is what they call HPL (High Pressure Laminates). Also, the ink needs to stay where it is during impregnation, at the same time the ink can’t contain a binder as the melamine would not penetrate the paper and this would not allow it to be pressed correctly, creating delamination and bubbles. So, the complexity of this technology just becomes a lot bigger than just printing a banner or poster.

As I started to understand the market better, I also looked at how to print and if we could use other technologies, such as printing with UV inks, but that would create a film on the paper. The result: The UV layer would not allow the resin to penetrate the paper. Sublimation inks would be too slow for the process and you would need to use expensive polyester materials to get the job done. Our industry really had to think differently and reinvent the way we look at print. Industrial print is the name of the game.

After years of testing and developing, the first printer product line became available. The first public release of this specially made product for the surfaces market was around the end of 2020. It included a water-based non binder ink with the correct pigment colors in the inks, a color management software and separation engine for the surfaces industry, and the speed to match the need for sampling and short-run productions. The system is capable of printing 150-plus tons of paper per year, or for us mere graphics people, a little more than 20 million square feet per year. The total solution approach was needed as the current surfaces customers are relatively new to digital printing, and having it all in one hand makes it simpler and guarantees a stable production environment. Sure, it’s not a huge single pass system replacing their whole gravure line, but an industrial entry-level system. Still, for our sign and display industry, a top of the line system.

So, as we progress in this new industry we have to prove that our print quality, color, and reliability can become the main factors for choosing digital print. As we progress in time the conversion to digital will happen as it already did in screen, textiles, and general commercial print. I’m proud to look at all the surfaces around me knowing that someday they will all be printed digitally.

From starting my day with a shower surrounded by print to sitting at my desk in the office, walking to the company showroom on a nice laminate, watching sports on my TV that is standing on the new wood grain décor furniture I bought, my world has just become surface print.

PHOTO GALLERY (16 IMAGES)

Advertisement

VEHICLE WRAPS + GRAPHICS3 weeks ago

VEHICLE WRAPS + GRAPHICS3 weeks ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Case Studies3 weeks ago

Case Studies3 weeks ago

Case Studies1 week ago

Case Studies1 week ago

Benchmarks3 weeks ago

Benchmarks3 weeks ago

Press Releases2 months ago

Press Releases2 months ago

Press Releases3 weeks ago

Press Releases3 weeks ago

Press Releases2 months ago

Press Releases2 months ago

UR SIGN AND DISPLAY graphics industry is mainly dealing with the print production of huge or small billboards, posters, pop-up displays, soft-signage, and many other appealing commercial images. We’ve been working with retail and we sell our rhetoric of marketing image on a daily basis.

UR SIGN AND DISPLAY graphics industry is mainly dealing with the print production of huge or small billboards, posters, pop-up displays, soft-signage, and many other appealing commercial images. We’ve been working with retail and we sell our rhetoric of marketing image on a daily basis.