Manufacturers, end users, and researchers met for the second-annual “Digital Textile Printing Conference V2.0” hosted by the American Association of Textile Chemists and Colorists (AATCC) and SGIA in Durham, North Carolina, November 29-30. More than 130 attendees took part in the sold-out event.

Here are some of the top takeaways from the educational event:

Ron Gilboa, KeyPoint Intelligence: State of the Digital Textile Printing Industry: Technology and the Innovation that Drives Growth

• The apparel retail market is showing 6 percent growth until 2020.

• The wholesale value of digital textile printing will be $33 billion in 2021.

• Ninety percent of corrugated packaging is being recycled. How much recycling happens in textile printing? 01. percent of all clothing is recycled into new textile fiber.

Advertisement

• The case for digital textile printing?

Creativity: Large repeat sizes; print flexibility; and a variety of creative designs choices for printing.

Supply Chain: Short run printing; reduced production space requirements; less printed inventory needed; and sampling and production completed on the same printer.

Environment: Lower water and power consumption; less chemical waste; and low capital investment.

• Ongoing tech developments: Higher speed; growing single pass offerings; higher-end multi-pass systems of ranging speeds and capabilities; and direct and paper sublimation improvement.

• Challenges in digital textile printing: Reliable printheads; ink and media; and accessories (dryer, steam, wash inspect).

• Opportunities in digital textile printing: Democratize access to market; supply chain efficiency; and production efficiency.

Vince Cahill, VCE Solutions: Digital Textile Solutions – Matching the Technology to the Application

• Why digital textile printing? Cost-effective sampling, customization, and short runs.

Advertisement

• There will be 30 digital textile single-pass inkjet printers worldwide by 2018.

• Digital 2D and 3D printing technologies and textile fabrication methods are changing how textile products are designed, printed, and made.

• Textiles are becoming smart for medical and athletic wear, industrial use, architecture, public safety, and military personnel.

• The speed to market of digital print and internet sales are driving textile printers to adopt.

• Next hurdles: automate sewing, eliminate dye finishing water waste, and accurate color delivery.

Duncan Ross, AVA CAD CAM Group: Digital Textile Printing – An Impartial Guide to Choosing the More Suitable Technology for Your Business

Advertisement

• Choosing the right components is more important than ever before because the industry is getting competitive, more aware, more professional, and more innovative. There's an increase in players, and fewer “cowboys.”

• Key considerations when finding the right technology for your print shop: target market; expectations; print quality; speed; media; width; ink type; coatings; steam, wash, and transfer; colors; droplet size; warranty and support; staff training; water supply, utilities, recycle; and running cost.

• Successful digital printers regularly train their staff; staff who are trained and rewarded, stay loyal.

• When choosing the right digital textile printer, test: flats, solids, tonals, and photographics; your critical colors; speeds; passes; media; long print runs; color gamut; abrasion, rub, and wash; penetration; experience of your market; and don’t forget to read the small print.

Fabric for Digital Textile Printing: A Panel Discussion

• Consistency from product to product is a current challenge with digital textile printing. – Katelyn Lee, Cotton

• Having a profile for your fabric is the key to success. … With digital textile printing, it's all about systems and keeping everything running in one system. And if you do it the right way, it works. – Mike Sanders, Top Value Fabrics

• We want flexibility with color because we're going after a “look” for the fabric. We used to look at black as charcoal, and now it's actually black, so that's exciting. … Simplicity is a good thing. If you simplify the process you open a market opportunity. – Kerry King, Spoonflower, Big Picture Editorial Advisory Board member

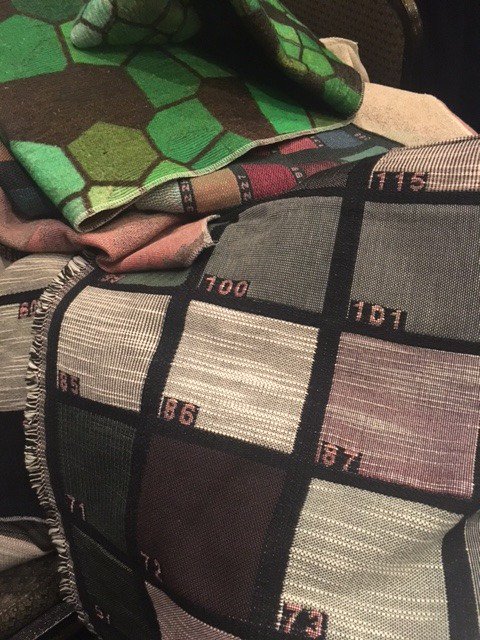

Claire Hider and Traci Lamar, North Carolina State University: Digital Inkjet Printing on Jacquard Woven Fabrics

• With digital textile printing, there's unlimited color options and unlimited potential in the home furnishing market.

Paolo Torricella, EFI Reggiani: How Textile Production is Shaping the Fashion and Textile Industries

• What are apparel industry customers asking for? Fast textile, going green, and competitive advantage.

• The future is demanding. You need to better, faster, and cheaper, and both global and local.

David Clark, Huntsman Textile Effects: Digitally Printed Fabric Requirements for the Automotive and Outdoor Furnishings Market

• Durability, color fastness, meeting brand specifications, and application know-how are essential to drive market growth in the automotive and outdoor segments.

• Process control and knowing your substrate are keys to meeting very high durability specifications.

• Brands and retailers will play an important role in the market conversion specifying digital print and building new business models.

Follow Editor-in-Chief Adrienne Palmer on Twitter for live updates from industry events.

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Columns2 months ago

Columns2 months ago

Blue Print2 weeks ago

Blue Print2 weeks ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago