Dave Merrick launched BIGraphics, Inc. (bigraphicsinc.com) in Nashua, New Hampshire, in 1996 as part of an unplanned midlife career change. “I got laid off in early 1996 as a product manager for desktop printers,” he recounts. “I was in my early 50s, and there wasn’t a lot out there. I went to a franchise show in Boston and ended up buying a turnkey wide-format printing system. My plan was to align myself with retail photofinishers and frame shops in my area and offer to print their customers’ photographs on canvas. Unfortunately, that business fell flat on its face. It wasn’t the other shops’ core business, so they didn’t push it.”

So, instead, Merrick turned his attention to other sources of printing business. “I started calling on designers, ad agencies, photographers, and so on, and built the business around them. Now we have about eight employees here.” BIGraphics operates with a Fujifilm Acuity HD, three solvent HP 9000s printers as well as a couple of aqueous Designjets, plus a ColorSpan 72UVR flatbed UV unit.

“Around 2005, I decided I needed a router,” Merrick says. “My son-in-law was an engineer, and he said, ‘Let me build you one.’ He put something together for me for probably no more than $8000. It had a vacuum table and used a Sears router as a cutting device. It worked like a champ, but we had to manually align our projects and hope the images were printed square. We made that work for a year or more.”

Eventually, though, Merrick decided he needed a real commercial router. He considered the ones intended for the sign industry, but decided they were overkill for his purposes. “They’re designed to cut metal and wood and we mostly cut foam board and plastic.” He finally decided upon the Gerber M3000 Flatbed Cutting System. “This thing is really powerful when it comes to cutting with knives,” Merrick says. “We can cut through 1/4-inch PVC with no trouble at all.”

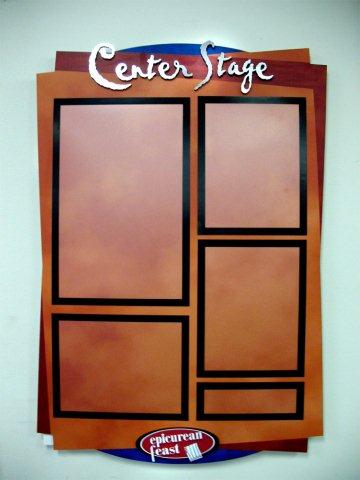

One project Merrick recently produced with the M3000 was a four-foot-high sign for an organization that manages company cafeterias for several corporations located in New England. The resulting sign looks like three sheets of wood stacked on a blue oval, but “it’s all one piece,” explains Merrick, “except the words Center Stage are on 3/16-inch brushed aluminum-faced acrylic, and the Epicurean Feast logo is printed in 6mm white PVC. They’re glued to the face of the sign.”

The background image—the three “sheets of wood” and the blue oval—was printed with the Fujifilm Acuity onto a rectangular piece of 6mm PVC. Merrick then used the Gerber M3000 to cut around the edges of the image to complete the illusion of separate pieces. The black frames are actually hinged pieces of transparent polycarbonate, behind which the company can slip pieces of paper with menus, specials, and so on.

Advertisement

Besides specific projects such as the Center Stage sign, Merrick also cites the ability the cutter gives him to make his own shipping boxes and display easels. “That’s a tremendous advantage,” he says.

BIGRAPHICS

www.bigraphicsinc.com

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Columns2 months ago

Columns2 months ago

Blue Print2 weeks ago

Blue Print2 weeks ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago

Best of Wide Format2 months ago