Case Studies

Can Print Shops Benefit from 3D Printing?

Drupa 2016 saw some big innovations.

Published

8 years agoon

Until now, the 3D printers at ISA, Graph Expo, and SGIA have been box-like devices that slowly print small models and doodads. That’s about to change, as larger, faster, more versatile 3D-printing devices will make it practical to offer 3D-printing services.

Before determining what types of services to offer, you must first understand that 3D printing isn’t really about “printing.”

In his book, “3D Printing Will Rock the World,” intellectual property attorney John Hornick explains why 3D printing may become one of the most disruptive technologies in human history. He cites dozens of ways it’s revolutionizing manufacturing, healthcare, architecture, and design. In addition to triggering businesses, products, and jobs we can’t yet imagine, Hornick says 3D printing will raise complex issues for brand owners, law enforcement agencies, and governments.

Like 2D printing, 3D printing is a catch-all phrase for many different processes. While some 3D printers use “jetting” technologies that have evolved from inkjet printing, many use processes that aren’t like printing at all. For example, devices that use direct and selective laser sintering melt metal powder to form the object.

Over the next 20 years, thousands of different types and sizes of 3D printers may be developed. The goal is to take 3D printing beyond modeling and rapid prototyping and bring it into the vast realm of product manufacturing. Students currently experimenting with 3D printers in classrooms may grow up believing that 3D printing is the most efficient, least wasteful method of making things.

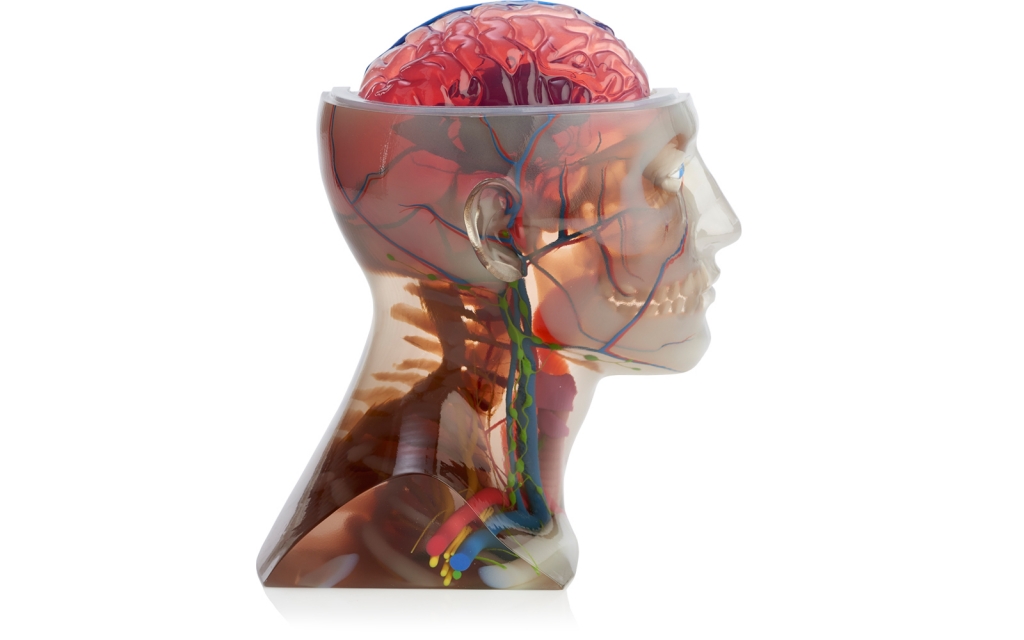

For product manufacturing, there won’t be a one-size-fits-all printer. Smaller printers will be used in homes, garages, schools, and libraries. Service bureaus and corporations will use bigger, faster, professional-grade 3D printers that can work with a variety of materials. Manufacturers will use industrial-grade 3D printers that print metals, electronics, or highly specialized materials. Healthcare organizations will use “bio-printing” materials to make replacement organs or prosthetics.

AdvertisementWhat Role Will Print Shops Play?

Hundreds of 3D-printing service bureaus already exist, Hornick says. Some are traditional machine shops that have added 3D printers to their capabilities. Other  “fab labs” are focused entirely on 3D printing and have been doing rapid prototyping for years. Most 3D-printing bureaus serve local companies, because 3D printing makes it possible to manufacture parts close to where they will be used.

“fab labs” are focused entirely on 3D printing and have been doing rapid prototyping for years. Most 3D-printing bureaus serve local companies, because 3D printing makes it possible to manufacture parts close to where they will be used.

As 3D printers become bigger, faster, and more capable, manufacturers will no longer have to spend huge amounts of time, energy, and money to ship products from a centralized factory to stores and consumers throughout the US. Instead, manufacturers can deliver the digital files to a 3D printer in a local service bureau or in the consumer’s home.

While this 3D printing scenario will disrupt retailing and long-haul trucking, it has already attracted the attention of three organizations with expertise in home deliveries: The UPS Store, Amazon, and the United States Postal Service.

“If I were already in the printing business, I would study which 3D-printing technology is appropriate for the type of work I’m already doing,” Hornick says. For graphics companies that already use inkjet printers to make short runs of customized products, 3D printing might be a natural fit.

David Regan, CEO of the Semper International staffing agency, envisions that bigger commercial printing companies could use large 3D printers to manufacture furniture and other large objects that would be impractical to produce at home.

3D Printing at Drupa

3D printing has proved a key part of the “Touch the Future” theme at the drupa 2016 show in Düsseldorf, Germany. In the 3D fab + print touchpoint in Hall 7a, thought leaders, industry professionals, exhibitors, and visitors have discussed ideas and technologies for 3D printing package designs, displays, parts, and products. Presentations touched on topics such as:

• Which 3D technologies are relevant to the 2D-printing and packaging production industries?

• What added business potential exists for 2D-printing services to integrate 3D printing?

• What opportunities does 3D printing represent as a new business model?

You might also notice a growing crossover between 3D printing and functional printed electronics. In the future, it might be economically feasible to 3D print both the external structure of a product and the internal electronics.

Massivit 1800: Fast Output of Large Objects

At drupa, Massivit 3D conducted the first live demonstrations of a fast large-format printer for making custom displays, exhibits, and props for promotions, retailing, museums, theaters, movie sets, events, and themed environments.

Featuring a proprietary, patent-protected Gel Dispensing Printing (GDP) technology and a build rate of 1 foot per hour, the Massivit 1800 can print objects up to 6 feet high. The dual-process option allows two different objects to be printed simultaneously. And the print software can build “support-less” objects that consume less material.

Featuring a proprietary, patent-protected Gel Dispensing Printing (GDP) technology and a build rate of 1 foot per hour, the Massivit 1800 can print objects up to 6 feet high. The dual-process option allows two different objects to be printed simultaneously. And the print software can build “support-less” objects that consume less material.

In the GDP system, a high-speed printing and curing engine controlled by Massivit software dispenses layers of Dimengel. This white photosensitive polymeric material solidifies into a hard polymer after it’s exposed to UV light. Unlike the UV-curable inks that graphics printers eject as droplets, the Massivit printer dispenses Dimengel in a continuous process, like 1-millimeter strands of spaghetti.

The 3D-printing gel is non-flammable and has structural strength similar to that of the ABS thermoplastic resin materials commonly used in 3D printing. The white printed object can be smoothed, painted, or wrapped with self-adhesive vinyl.

AdvertisementThe properties of the gel and the curing speed enable the GDP technology to print faster than existing 3D technologies.

The three co-founders of Massivit 3D are thoroughly familiar with the visual communications markets served by Big Picture readers. Gershon Miller, Moshe Uzan, and Igor Yakubov were all involved with Idanit, the Israel-based startup that introduced the first high-speed wide-format inkjet printer for outdoor advertising graphics in 1996 (the Idanit-162Ad). Idanit was purchased by Scitex, rebranded Scitex Vision, and later acquired by HP.

While Uzan and Yakubov held research and development positions with HP Scitex, Miller co-founded Objet, a developer and manufacturer of 3D printers that merged with Stratasys in 2012.

“The large-format printing market has come a long way since it started about 20 years ago,” says Lilach Sapir, VP of marketing for Massivit. “We believe a Massivit 1800 can add another dimension to the business of print service providers.”

Unless you have worked with a desktop 3D printer, you may not realize how fast the Massivit 1800 3D printer is. Sure, it takes five hours to build a 5-foot-tall display. But that is blazingly fast compared to devices that build models at the vertical rate of 1 inch per hour.

The first Massivit 1800 in the US was installed in February at Carisma Large Format Media in Brooklyn, New York. The Massivit 1800 immediately went into production on projects related to moviemaking, museums, and a Times Square attraction.

According to Fran Gidalowitz of Carisma, the company had been looking for a large-format 3D printer suitable for their requirements since 2011. They learned about the Massivit last May and made a decision to buy it in July 2015.

“Our designers are all very creative, but we had never worked with a 3D printer before,” Gidalowitz says. “After Carisma signed the contract for the Massivit, we bought a small 3D printer and taught ourselves how to design and create 3D models.” They also hired a full-time 3D designer. By the time their production team went to Israel to learn to operate the Massivit 1800, they understood the basics of what it takes to create a 3D model. Now, the Carisma crew is experimenting with a range of finishing options, including vinyl wraps and painting and coating techniques. In addition to making props, they will use it to produce signs and promotional displays, and may even add 3D elements to bus wraps.

Highcon Euclid III with 3D Modeling Package

Another device that will be able to create 3D models, prototypes, and objects isn’t a printer at all. It’s the Highcon Euclid III, a digital cutting and creasing machine that converts printed B1 sheets of paper, cardboard, labels, and microflute into creative pop-up graphics or visually distinctive packaging. The Highcon Euclid III is marketed to commercial printers, trade finishers, and producers of small folding cartons.

At drupa 2016, Highcon showed how an optional 3D modeling package can use the variable-data cutting capabilities of the Euclid III and a Rapid Layer Manufacturing process to convert stacks of paper into P-O-P displays, signs, molds and masters, theater and movie props, decorative objects, and furniture. The Highcon Euclid III will be able convert many types of substrates, including waste paper, into 3D objects.

At drupa 2016, Highcon showed how an optional 3D modeling package can use the variable-data cutting capabilities of the Euclid III and a Rapid Layer Manufacturing process to convert stacks of paper into P-O-P displays, signs, molds and masters, theater and movie props, decorative objects, and furniture. The Highcon Euclid III will be able convert many types of substrates, including waste paper, into 3D objects.

HP Multi Jet Fusion Technology

HP Multi Jet Fusion is a new, high-speed, inkjet-based technology for producing highly functional parts. It might enable enterprises, small businesses, and service bureaus to offer on-demand printing of functional parts or customized products at affordable prices.

In a post on HP’s 3D Printing blog, J. Scott Schiller, the worldwide business director of HP’s 3D Printing Business, says, “In the nearer term, we see that HP Multi Jet Fusion technology has the potential to dramatically accelerate the product development cycle – it could even be used to rapidly iterate, enabling fast feedback from consumers so that hardware product development can mimic agile software development processes. In the longer term, our vision for the HP Multi Jet Fusion platform is that it will be a key ingredient to industrial transformation – fundamentally changing where, how, and why things are produced.”

Multi Jet Fusion Technology is based on HP’s background in inkjet printing, inks and jettable agents, precision low-cost mechanics, and material sciences.

“As with many 3D-printing processes, HP Multi Jet Fusion technology starts by laying down a thin layer of material in the working area,” Schiller explains. “Next, the carriage containing an HP Thermal Inkjet array precisely deposits chemical agents across the full working area. Finally, the energy, layering, and printing processes are combined into synchronized, area-wide sweeps, layer by layer, until a complete part is formed.”

Over time, HP Multi Jet Fusion technology will be offered in many types and sizes of printers, just as HP’s thermal inkjet printing technology evolved from desktop inkjet printers in the ’80s to today’s high-speed HP PageWide and HP Scitex industrial inkjet printing systems.

The first 3D-printing systems with HP Multi Jet Fusion technology will use thermoplastic materials. Future printers might be suitable for use with ceramics or metals.

Other Companies to Watch

Other manufacturers of digital printing devices that are working on 3D-printing systems include Canon, Konica Minolta, Ricoh, and Toshiba.

Earlier this year, Stratasys announced Creative Colors Software powered by the Adobe 3D Color Print Engine for Objet Connex3 3D printers. The software combines advanced color management with a streamlined direct design-to-3D-print workflow to make it easier for more designers to get involved in 3D printing.

combines advanced color management with a streamlined direct design-to-3D-print workflow to make it easier for more designers to get involved in 3D printing.

The new Stratasys J750 3D printer will be able to create more realistic-looking prototypes. Customers can choose from more than 360,000 different color shades and multiple material properties. The machine can be loaded with six different resins at once that can produce parts with different textures or properties (e.g., rigid, flexible, opaque, or transparent).

How Will 3D Printing Affect Staffing?

According to Semper’s David Regan, 3D printing might create some profound changes in the workforce.

Semper specializes in helping all types and sizes of printing businesses and creative agencies find people with the skills required to adapt to all the changes occurring in design and production. Because the firm supplies prequalified employees for short- or long-term flexible staffing, they are often on the forefront of workplace changes.

Regan has been watching the emergence of 3D-printing technology for the past few years and believes the workforce changes within printing companies might be just as challenging as some of the changes commercial printing firms made during the evolution from large offset print jobs to shorter runs of more personalized digitally printed jobs.

While 3D printing will bring new opportunities to commercial printing firms, Regan says not many clients are asking for employees with 3D printing experience yet. That’s because most commercial-grade 3D printers are used to prototype parts for complex manufacturing projects such as airplanes, battleships, and automobiles.

To advise clients of the types of employees they should recruit for the next wave of disruptive technologies, Semper recently published a white paper, “How 3D Printing Will Change Everything,” and an e-book, “Meet the TechCreative.”

“With unforeseen design freedom, affordable customization, environmental benefits, lower costs, and local production, all who embrace 3D printing will have a competitive advantage,” Regan says.

Printing companies that want to get involved with 3D printing will either have to retrain current employees or hire people with the skills to create digital designs and oversee production from dozens of 3D printers.

Semper encourages all clients in the graphics industry to retain or recruit “TechCreatives” – creative people who constantly update their technical skills so they can shepherd a client’s project from idea through delivery.

How Will 3D Printing Affect Society?

Governments, social-service agencies, and communities must prepare for the workforce disruptions that will occur as 3D printing transforms manufacturing and enables everyone to make their own products. Regan believes 3D printing could create a host of societal issues as millions of workers are displaced from jobs related to retailing, trucking, printing, and manufacturing.

In his book, Hornick explains how 3D printing might disrupt intellectual property and product liability laws and create new headaches for brand owners and law enforcement agencies.

If products can be scanned, altered, and manufactured anywhere and everywhere, who can say which products are “genuine” anymore? And if a product design is altered to avoid infringing on intellectual property rights, who will be held legally liable if the product fails?

Brand owners and product designers should think about ways to control their blueprints so their products will be made only by authorized manufacturers. Copy shops that offer 3D printing will need to be sure that their customers either own the design they want printed or are authorized to produce it.

Right now, no one can predict how quickly the use of 3D printing will grow and how the technologies might be used. All we know for sure is that 3D printing will bring major changes.

Hornick reminds us that when the computer, the internet, and the smartphone were introduced, no one really foresaw their full potential. But with the passage of time and some out-of-the-box thinking by innovators and entrepreneurs, these developments have become integral to how we live and work.

The same can be said for full-color digital printing. Over the past 25 years, continuing advances in digital printing and communications have forced thousands of businesses to retool their business models and production methods. At the same time, designers and entrepreneurs have created new applications and businesses that digital printing equipment manufacturers never imagined.

Read more on 3D printing or check out our May 2016 “Running the Tables” issue.

SPONSORED VIDEO

Printvinyl Scored Print Media

New Printvinyl Scored wide-format print media features an easy-to-remove scored liner for creating decals, product stickers, packaging labels, and more. The precision-scored liner, with a 1.25” spacing on a 60” roll, guarantees a seamless and hassle-free removal process.

You may like

California Company’s Worst-Ever Typo? It’s a Funny Story …

3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

Konica Minolta Appoints Frank Mallozzi to President, IPP

This Wide-Format Pro Started at Age 11, and 32 Years Later, Still Loves What He’s Doing

Wide-Format Printers Share Their Thoughts on Business-Advice Books

3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

SUBSCRIBE

Bulletins

Get the most important news and business ideas from Big Picture magazine's news bulletin.

Most Popular

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoHere Are the Winners of the 2024 Best of Wide Format Awards

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

-

Columns2 months ago

Columns2 months agoHow Apps and Instruments Are Making Color Mobile

-

Blue Print2 weeks ago

Blue Print2 weeks agoThis Wide-Format Pro Started at Age 11, and 32 Years Later, Still Loves What He’s Doing

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoColorado Town Hypes Its Incredible Natural Gifts in City Hall Rotunda Project

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoPrivate Customer’s Bespoke Bathroom Wallcovering Showcases Their Passions

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoIllinois Print Pros Help Historic Toy Brand Create a Memorable Shopping Environment

-

Best of Wide Format2 months ago

Best of Wide Format2 months agoIconic Music Venue Celebrates Half-Century With Vibrant Exhibit of Rock Artifacts